Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Dec 2024

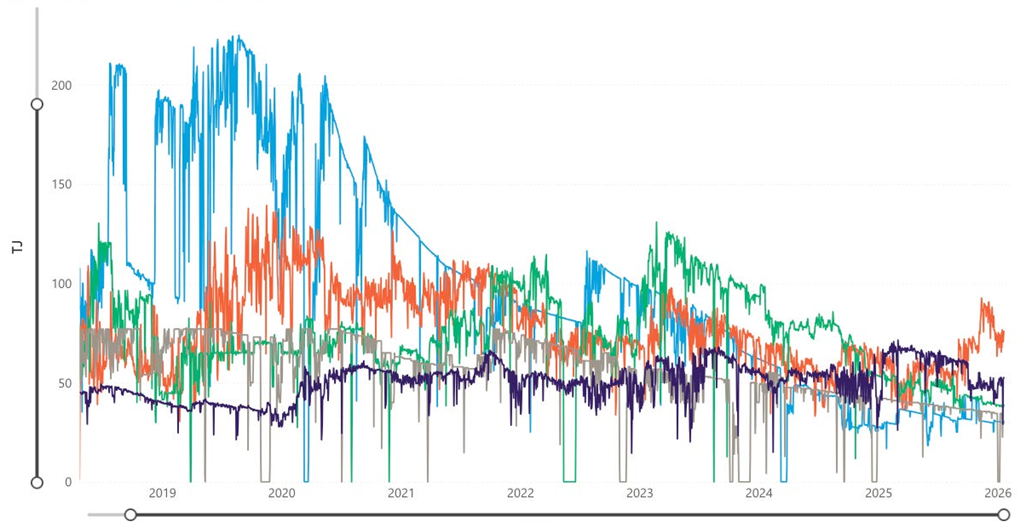

2024 – The NZ greenhouse energy sector Grower2Grower report

Flicker of light at the end of the tunnel. What options make financial sense?

If I were to assess my progress in finding sustainable energy solutions for growers, I would rate myself a 5 out of 10 this year. It’s been a challenging year, but I remain committed, as do others, to continue pushing forward.

I have dedicated considerable time to exploring various energy options that may or may not be feasible for growers. I have analysed both capital and operational expenses, as well as calculated the kilowatt-hour values for each energy source I’ve investigated.

My conclusion is that there is currently no straightforward solution, and certainly no one-size-fits-all approach. Energy costs are high, and the volatility and unpredictability of prices put us at risk of being uncompetitive compared to imported hothouse-grown products. Additionally, there are legitimate concerns about increasing carbon food miles and the impact on domestic food security. My hope is that electricity can offer a long-term solution, but it must be commercially viable.

Below is a list of energy options, ranked from the most expensive to the least expensive, considering both capital and operational costs, along with brief comments:

Heat Pumps/Electricity

- Capital expense – very high

- Operational expenses – high

- Heat storage system advised

- No CO2

Heat pumps come with several risk factors, including the challenge of securing long-term electricity contracts at reasonable rates. Given the coefficient of performance (unless starting with very warm water), they may end up being more expensive to operate than natural gas based on current estimates. If relying on air temperature, warmer climates can be an advantage—provided electricity supply is reliable.

The capital costs are significantly higher compared to other systems, but if these costs decrease, more growers may be able to consider this option.

One key benefit of heat pumps is that they use renewable energy, which ideally has minimal impact on climate change (assuming grid electricity isn’t generated from coal or natural gas). Another advantage is that air discharge consents are not typically a concern.

Natural Gas

- Capital expense – Low

- Operational expenses – high (due to gas prices)

- Heat storage system advised

- Free CO2 option

Undoubtedly, this has been the most effective solution for growing affordable produce. Growers make significant use of the CO2 from the chimney, directing it into their greenhouses to be absorbed by plants, which offers valuable production benefits. However, the future availability and reliability of natural gas is highly uncertain. With the rising costs of the Emissions Trading Scheme (ETS) and the potential reduction in carbon credits for growers, natural gas has become the second most expensive energy source. Future contracts could be prohibitively expensive, and there is a risk that they may not even be available.

Processed Wood Pallets

- Capital expense – medium

- Operational expenses – High (due to price of product)

- Heat storage system advised

- Additional shed storage required with moving floors and augers

- No CO2 capture

Dry wood pallets require less storage and tonnage comparable to other biofuels. The issue is the price of the product and long-term supply contracts.

Hog Fuel

- Capital expense – Very High

- Operational expenses – High (due to volume required/transport)

- Heat storage system advised

- Additional shed storage required with moving floors and augers

- No CO2 capture

This option seems attractive but to burn hog fuel you really need a Furness before the boiler or an expensive high-tech burner. The hog fuel of wet wood chip is low in gigajoule value per ton and therefore you need lots of it. Unless you chip on site or have your own sawmill this is not an ideal solution. Other considerations are constantly increasing transport charges.

Briquettes

- Capital expense – Medium

- Operational expenses – Medium (due to volume required/transport)

- Heat storage system advised

- Additional shed storage required with moving floors and augers

- No CO2 capture

Due to quotes received for the briquettes this is a slightly higher operational cost than dry wood chip.

Dry wood Chip

- Capital expense – Medium

- Operational expenses – Medium (due to volume required/transport)

- Heat storage system advised

- Additional shed storage required with moving floors and augers

- No CO2 capture

Out of all the wood or biomass options dry wood chip was the most attractive of all the wood options. Potentially old coal boilers could be converted to using dry wood chip which could lower capital cost for smaller existing systems. Growers that have access to dry woodchip within 100 km should consider this option. Long-term supply contracts are critical as you have to trust you will have all year supply.

Recycled Oil

- Capital expense – Low

- Operational expenses – Low

- Certified storage tanks required

- No CO2 capture

Recycled oil based on current prices is the best bang for buck if you are not located near any geothermal activity. Many growers have already moved to recycled oil especially new builds as it is so cost effective. I personally started growing using recycled oil before switching at some point to Natural Gas. The downside with recycled oil is the cleaning and maintenance. You are not able to use the CO2 from the chimney due to the impurities in the oil. Supply may decrease as demand increases, so current pricing may change!

Geothermal

- Capital expense – Medium

- Operational expenses – very low

- No CO2 capture

Geothermal or warm water options are ideal however you need to be fortunate to have your greenhouse close to a source. For any big operation looking to harness geothermal you should consider being part of a network of bores. The other big considerations are generally where geothermal is located as the land may not be ideal for building, and you may be more prone to earthquake risk increasing insurance risk. If you have any type of warm water, you could even consider a hybrid system with heat pump technology/electricity.

Possibly low-tech plastic house structures may be more favourable due to the issues around ground stability – it is worth considering. There is one large site in NZ that has its energy from Geothermal and it works extremely well so it can be done.

NOTES:

I have not included electricity from Solar Panels, however, in the future this could be a way of allowing heat pumps to work effectively for all but a few winter months. I understand that is when we need the heating the most, but a hybrid solution could provide alternatives.

Coal is not part of my report, but coal sits like natural gas, however unlike natural gas you can not use the CO2 out of the chimney for the plants.

New rules and consents (depending on the size of your boilers and operations) required CO2 emissions including air discharge consents are now in place. You need to be aware of this. This effects both existing systems and new builds.

Growers have also come into the firing line for new boiler consents and must show CO2 reduction plans. Even brand-new builds with all the newest technology require CO2 reduction plans even if plants supplemented with the CO2.

For more information please e-mail stefan@grower2grower.co.nz

CLASSIFIED

Photo

Gallery

Subscribe to our E-Zine

More

From This Category

New Zealand’s 2026 Energy Stock-Take – Part 2 – Natural Gas

Best of 2025 – 79.2% decrease in Emission Trading Scheme (ETS) allocations for South Auckland Cucumber Grower

Ball Australia Boosts Climate Control with New Blackout Screen Upgrade

Why energy is now a strategic risk (2025 Grower2Grower overview of energy and looking forward)

Online workshop : learnings from the low-energy input trial for greenhouse tomatoes