Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Mar 2023

Achieving operational efficiency with a precise match of technology to business processes

New Zealand’s largest greenhouse, Southern Paprika shares their story

Southern Paprika specialises in capsicums and has become the largest single-site greenhouse operation in New Zealand, with over 27ha (67 acres) of state-of-the-art greenhouses. They have adopted an approach of continuous improvement, whereby they are constantly comparing and developing new methods, processes and inputs in parallel. This allows them to continually refine their practices, thereby achieving ongoing incremental productivity and efficiency improvements.

After using a labour management system from a large and well known brand, Southern Paprika recognized that this system was primarily geared towards using a set operational approach, and that it could therefore not align easily with their specific business processes. This meant that potential efficiency gains were being left unrealized. Southern Paprika required a software system that could meet multiple criteria: a match to their processes, featured easy to input performance data into their continuous improvement model, and which came at an affordable cost.

(Above) Liam Griffin, site manager at Southern Paprika Limited

To achieve this, they partnered with BumperCrop, which by now has over 4 years of experience in developing and implementing greenhouse labour and operation management systems. This allowed them to have the best of both worlds – immediate access to a powerful and flexible labour system, while avoiding the high costs and lengthy timeline of building and maintaining their own system.

A key attribute of the solution required by Southern Paprika, was to record the precise amount of produce coming from each row, in a way that would be quick and easy for workers to implement. The solution entailed integrating portable and battery powered scales that directly transmit weight data into the existing BumperCrop App. Combining these scales with BumperCrop’s tag scanning system has created a flexible and accurate way to collect weight data from each row immediately after it is picked. Collecting weight data into the system now simply requires scanning a tag on each bin. The system also automatically subtracts the precise weight of individual bins, leading to greater accuracy than by using an average weight across all bins.

Video: collecting weight data from bins is simple’

https://drive.google.com/file/d/1FAbsuIpDdBOUO5m8okBDCEHbplcMiv6j/view?usp=share_link

BumperCrop’s wireless scales are available in multiple formats including crane, portable flat scales, heavy duty scales and load cells.

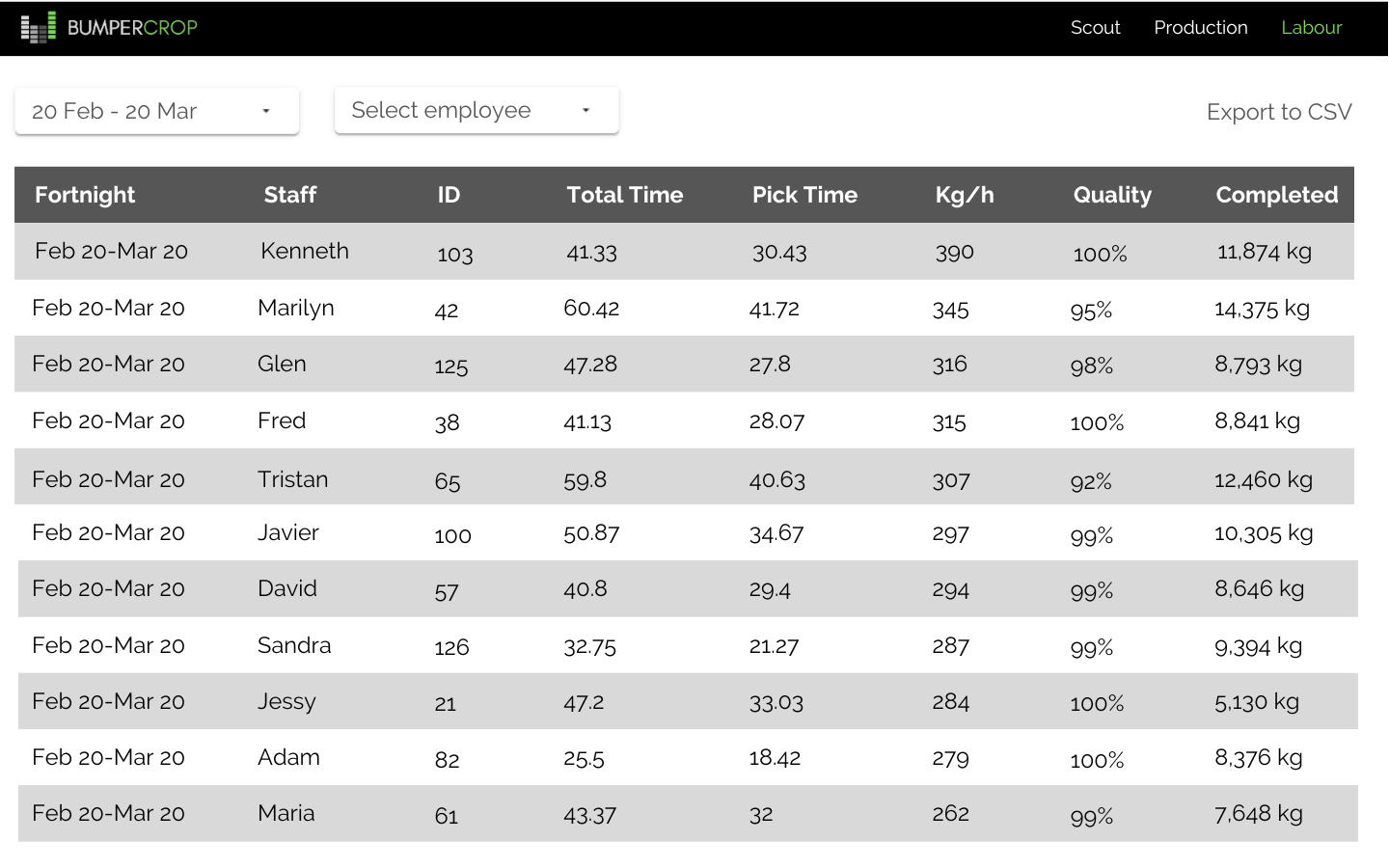

The weight data that is collected is used as the basis for decision making on which rows are performing the best. The BumperCrop system combines this with information about each row, such as the variety, number of plants and various methods and processes that are being tested to provide precise feedback into their continuous improvement model.

This data is also used to incentivise workers and improve labour performance by, for example, paying bonuses based on performance. Data is reported in the exact format required by Southern Paprika in order to integrate it into their existing systems. This includes the addition of employee ID numbers, formatting of the data columns and timeframes for integration with their payroll system.

For more information:

BumperCrop

+64 27 3512512

CLASSIFIED

Photo

Gallery

Subscribe to our E-Zine

More

From This Category

Tomato grower applies Tobre after contamination

KWS inaugurates new R&D facility in Uberlândia, Brazil

Powerplants and RTF Climate Announce Strategic Partnership for the APAC Region