Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Mar 2021

Autumn is here

Fruit load and stems per m2

Autumn is officially here but I don’t expect plant growth or setting speed to slow down for at least the next three weeks. Light is rapidly reducing but it is still sufficient, plus it is still warm. As I wrote about in another of my article’s this week, I am concerned with growers keeping up with work load. Generally, I would wait possibly a week or two longer (every crop differs) before reducing stems, but it may be a consideration to reduce head numbers now. Whitefly numbers have also increased so I would be considering reducing plant stress to combat both insect pressure and the current glut in the market. I believe prices will firm in the coming weeks, cherry tomato prices and cucumber prices have already firmed which is fantastic.

I would keep the pedal to the metal for cucumbers and only when they start to show stress reduce fruit numbers as they will regain vigour quickly. For long crop tomato growers, it is different. Certainly, I would be looking at the long game and making sure that I had a very healthy plant at the beginning of May so the fruit that is set then harvested in July is of the highest quality. Easier said than done but this again is when solid returns will be made. If growers are able to look after their crops and get through this lockdown and possible further lockdowns it will also give the market certainty of supply and prices hopefully will not be out of reach for many consumers.

Export figures for January 2021 compared to January 2020 are bleak and show a reduction of over 380,000kg fresh tomato exports for the same periods year on year. This is either a direct reflection of the shipping issues or disruptions from our usual export markets that Covid-19 has caused. It doesn’t really matter if was either or a combination it is now in the past and we must look forward as the seasons change.

Controlling pest insects and fungal issues may be another concern, simply due to the lack of workers to carry out control tasks. I find that March and April are crucial for staying on top of any of these issues. If they get out of control it will directly impact on winter production.

Below is an article I wrote two years ago in regards to reducing stems per m2. If you have time, and it is applicable to your situation, it may be relevant for you to read again.

news/post/reduce-stems-per-m2/

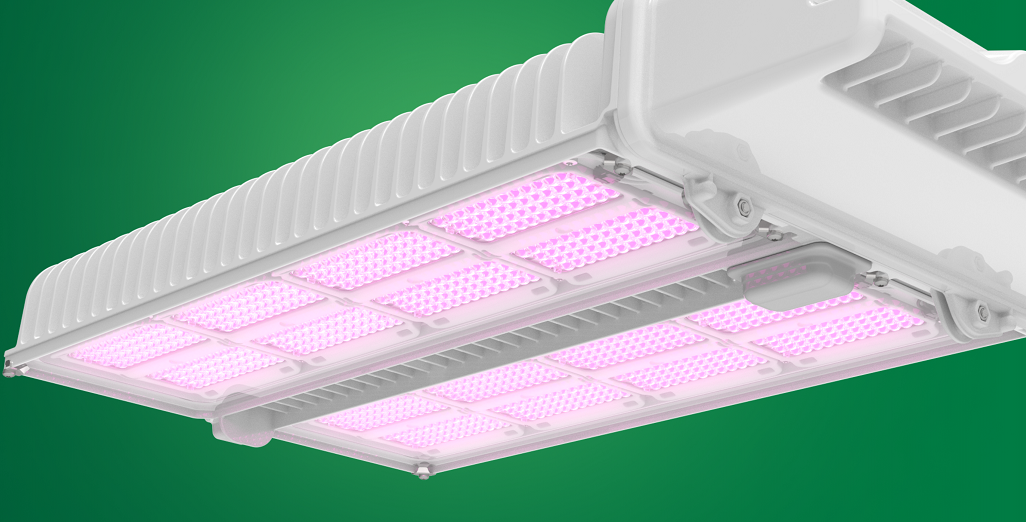

As April fast approaches it is very easy to forget, with the beautiful weather we have had, that winter is just over two months away. For tomato growers, who still have summer stems per/m2 planting density, there is still enough light to support the summer stem density and the fruit. It is easy to observe how strong the plants are and how they are easily coping with summer density. However, in seven weeks when the flowering truss is close to harvest you will end up in a potential pickle unless you have already pinched the heads on the extra stems. The only exception to this is if you have artificial lighting.

Tomato growers, who planted in December and January and planted at summer density you will have started picking already. Many growers now plant with a Triple Headed Grafted (THG) plant in December or January for several reasons. Double Headed Grafted (DHG) can be difficult to control from becoming too strong/vegetative, even if growers take an extra side shoot after planting. With a triple you have a better chance of controlling and balancing a plant with the added benefit of planting straight away at summer density. If you time it correctly you should be able to get a minimum of eight trusses set form this extra stem before removing their heads and going back to your winter density. Please see article news/post/triple-headed-grafted/

If the extra heads have not been removed by now you could find that later in autumn you will create unnecessary stress on your plants, which could adversely affect plant health. Growers I consult to, that planted THG, are currently having a higher degree of success with both the balance of their plants and a huge increase in production compared to planting DHG at similar times to previous seasons. There is extra work involved, including having several different coloured strings to identify the shoot that needs to be removed, but this also gives the grower the option to increase to summer density again in early spring. By having different coloured strings, it is easy to identify and make sure you have three heads all coming off the same block. If you don’t do this you run the risk of some blocks having four heads and some staying at two. To explain to non-growers, who are not familiar with layering systems, when plants are layered it is not easy to trace back what stem belongs to which block/bag because the stems are already very long and entangled. The string takes the guess work out of the equation.

Article written by Stefan Vogrincic

All Article’s checked and edited by Marie Vogrincic

I appreciate your comments. Please feel free to comment below or on the grower2grower Facebook page:

CLASSIFIED

Subscribe to our E-Zine

More

From This Category

Ground cover: woven weed mat or solid plastic… or both?

Integration of Philips GrowWise control system with climate computer allows Huisman Chrysanten to light more effectively and efficiently

New Philips GreenPower LED toplighting force 2.0

Condensation re-visited

Philips GrowWise Research Center to test and showcase intelligent lighting