Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

May 2024

DENSO and Certhon introduce Artemy®:

A fully automated cherry truss tomato harvesting robot

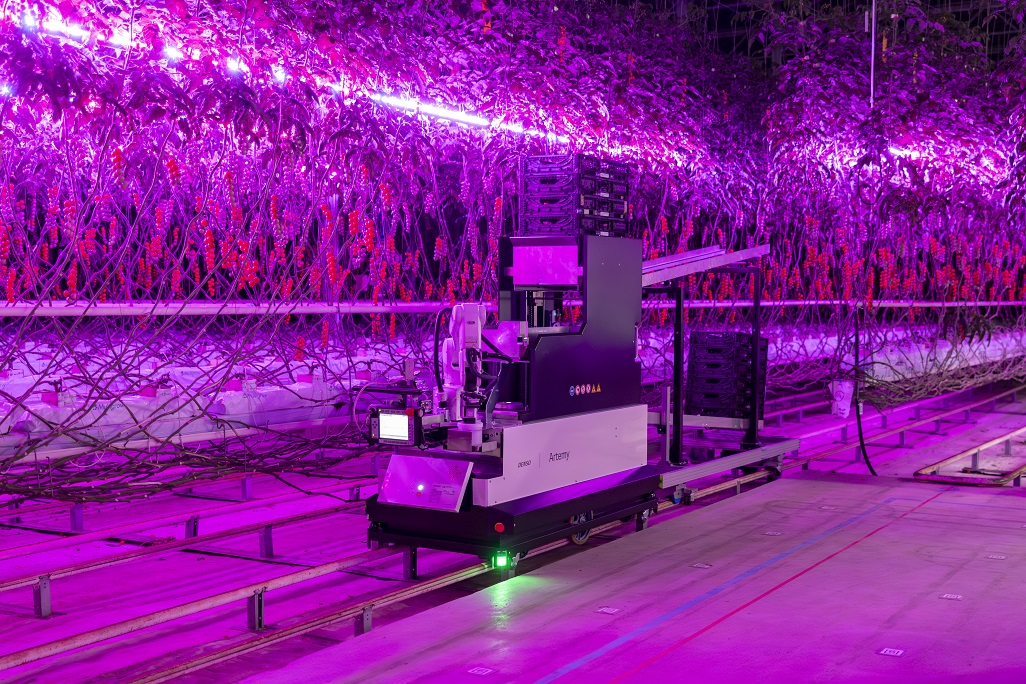

KARIYA (Japan) ― Artemy is the brand-new harvest robot developed jointly by DENSO Corporation and Certhon, and it is ready for the commercial market. The robot is equipped with advanced vision technology for scanning the crop by its maturity and harvests ripe truss tomatoes. Artemy has an automatic lane change function, utilizing the sensor and image recognition technology to recognize running lanes so it can move to the adjacent one, even in trackless environments. In addition, Artemy has several other functions, such as automatic replacement and transfer of crates, which reduce heavy work for farmers.

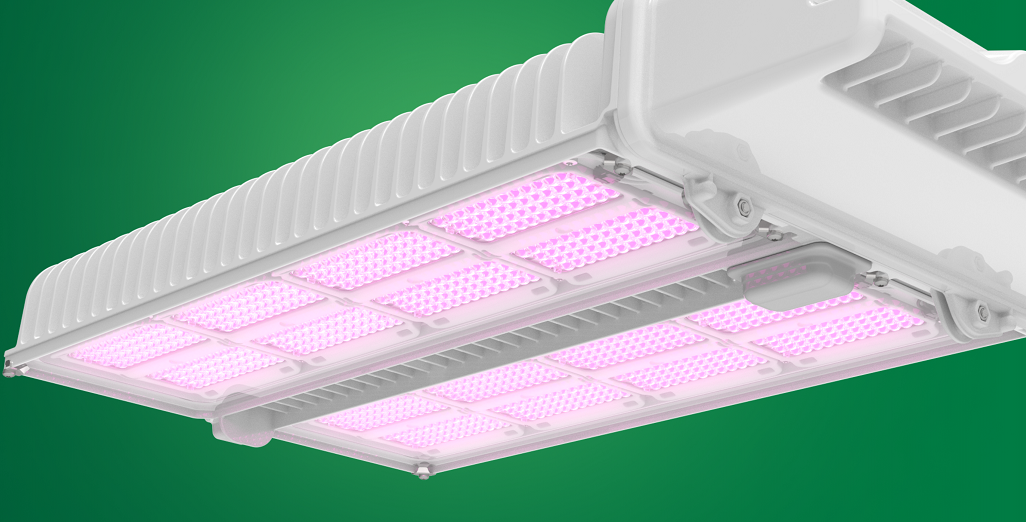

Artemy is equipped with several functions that contribute to the alleviation of labor shortages and the reduction of heavy labor. Ms. Lotte van Rijn, CEO Certhon, explains: “For example, the automatic lane-change function allows Artemy to autonomously move between running lanes, a long-awaited function.” It works alongside those present in the greenhouse in an incredibly safe manner as it stops when obstacles are detected along the lane. By equipping Artemy with a cluster and a peduncle detection LED, as well as replaceable batteries, it is possible to operate continuously regardless of day or night and under LED. When all crates on Artemy are full, it automatically moves to the cart with empty crates and replaces them all at once, after which it continues harvesting.

In recent years, the field of food and agriculture has increasingly faced issues with unstable agricultural production due to climate change and a decrease in the farming population. There is a necessity for the establishment of a stable and sustainable agricultural production system with cultivation methods that are not affected by the climate, alleviate labor shortages, and reduce heavy labor. Mr. Hidehiro Yokoo, Senior Executive Officer of DENSO Corporation (Food Value Chain Business Development Division), adds: “DENSO’s expertise in mobility and manufacturing, encompassing image recognition, safe driving, and robotics, is integrated into all of Artemy’s operations, from the automatic harvesting of cherry truss tomatoes to the automatic lane changes. Going forward, DENSO will continue to combine its technology with Certhon’s cultivation know-how and horticulture technology to achieve the stable production that DENSO and Certhon aim for worldwide, making ‘Growing anything, anywhere. For everyone.‘ possible.”

It is both DENSO’s and Certhon’s mission to keep contributing to the realization of sustainable agriculture worldwide. Having started with Artemy, they aim to do so by continuing to develop productivity-enhancing solutions that can handle multiple varieties and take over other tasks in the greenhouses.

For those interested to see this significant progress in robotization; Artemy will be shown to the public at GreenTech Amsterdam, the world’s largest horticultural trade show, hall 5, stand 05.250 (held from June 11 to 13, at RAI Amsterdam, in The Netherlands).

Photo 1: Fully automated cherry truss tomato harvesting robot “Artemy”

Photo 2: Automatic lane change

Photo 3: Automatic crate transfer

About DENSO CORPORATION

Headquartered globally in Kariya, Japan, DENSO is a leading mobility supplier with $47.2 billion in sales and develops advanced technologies and components for nearly every vehicle on the market today. DENSO is also expanding its range of value offerings to include factory automation, food, and agriculture, with automotive technology at its core. For more information about DENSO’s operations worldwide, visit https://www.denso.com/global.

About Certhon

As the number one high-tech innovator, with more than 125 years of experience in the horticulture business, Certhon enables its horticulture partners to grow anything anywhere in the world. Irrespective of the climate or the amount of daylight. Certhon develops, produces, and creates tailor-made solutions, such as high-quality greenhouse projects, indoor farms and robotics. By combining smart technology, agronomy and having all expertise under our own roof, we reach true and sustainable success. For more information about Certhon, visit www.certhon.com.

CLASSIFIED

Photo

Gallery

Subscribe to our E-Zine

More

From This Category

Ground cover: woven weed mat or solid plastic… or both?

Integration of Philips GrowWise control system with climate computer allows Huisman Chrysanten to light more effectively and efficiently

New Philips GreenPower LED toplighting force 2.0

Condensation re-visited

Philips GrowWise Research Center to test and showcase intelligent lighting