Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Apr 2019

Fruit load per m2 using temperature and available light (part 1)

Less fruit load more speed

This week’s articles, although different, follow a pattern. It is an important time to start working on the little things that could vastly improve productive outcomes. Fruit numbers m2, especially as we are heading towards May, is a very important topic of discussion. For tomatoes, anything that is flowering and setting now will be not be harvested before we are well into the winter period. Harvesting speed, for each different crop, will be dependent on inputs. As growers, in general, will have different stem densities I feel it is probably best I tackle an article regarding fruit per m2.

What got me thinking?

While walking through a standard, loose, round tomato crop, picking at truss 5-6, it was interesting to come across a plant that had a truss broken. There was only two trusses above where it was missing and four and a half below. So not too far from the head, which is important to note as the fruit on that truss, on the other plants around it, were still small, so visually you think how could this small truss have consumed so much energy? What was noticeable was the immensely larger fruit, which was on the lower trusses, compared to the plants that had not lost a truss.

When I first started using a consultant, as a grower, I was always instructed not to remove a truss as this would throw out of kilter, the balance of the plant. I still agree with that; I think the total removal of a truss becomes a necessity because of a plant health issue or incorrect management decision to overload the plant, which could in turn have caused a health issue. Never the less, and whatever the reason this particular plant poses some questions.

What is the correct fruit numbers per m2?

There will be many theories answering this question but with detailed crop registration, over the years, most growers have been able to gradually come up with numbers that have been workable. We have an agreed number of fruit m2 in our heads and using this number, and calculating the predicted available light will then come up with advised temperatures to match the fruit numbers. The problem with these estimates is that it is not a perfect science, no algorithms (yet), just years of learning and predicting. What I have come to realise is that less fruit, and harder pruning, could potentially yield slightly less production but it will realise fruit size that will reach premium price.

Increased temperature with lower fruit per m2?

The most important question I have is ‘if we have less fruit per m2 how much more speed/temperature can we gift the plant in late Autumn/Winter?’ If, all of the plants used in my example, had a truss removed then there would’ve been a need for a much higher twenty-four hour temperature to ‘speed up’ the ripening process. The fruit were becoming too big, and soon would be in a lower price bracket, so the only way to pick this fruit off faster would be to increase temperature and therefore increase speed. With winter approaching we look to drop our twenty-four-hour temperature, as we don’t have the light to grow with speed, but if we looked at further reducing our fruit load, we would, in theory, be able to grow with a higher twenty-four-hour temperature. If you are energy conscious then please don’t worry because I believe this could be achieved using increasing day temperature on light, or a day boost. There are also plant health advantages, if you have warmer pipe temperatures for example.

Suggesting fruit loads per m2 comes from experience, but I believe new technology and evolution will one day have a computer algorithm spurt out exactly what we need but until then we must use our crop data to make the most informed decision possible.

I appreciate your comments. Please feel free to comment below or on the grower2grower Facebook page:

https://www.facebook.com/StefanGrower2grower/

Article Written by Stefan Vogrincic, Consultant, Grower2Grower

Article Edited by Marie Vogrincic, Editor, Grower2Grower

CLASSIFIED

Subscribe to our E-Zine

More

From This Category

Ground cover: woven weed mat or solid plastic… or both?

Integration of Philips GrowWise control system with climate computer allows Huisman Chrysanten to light more effectively and efficiently

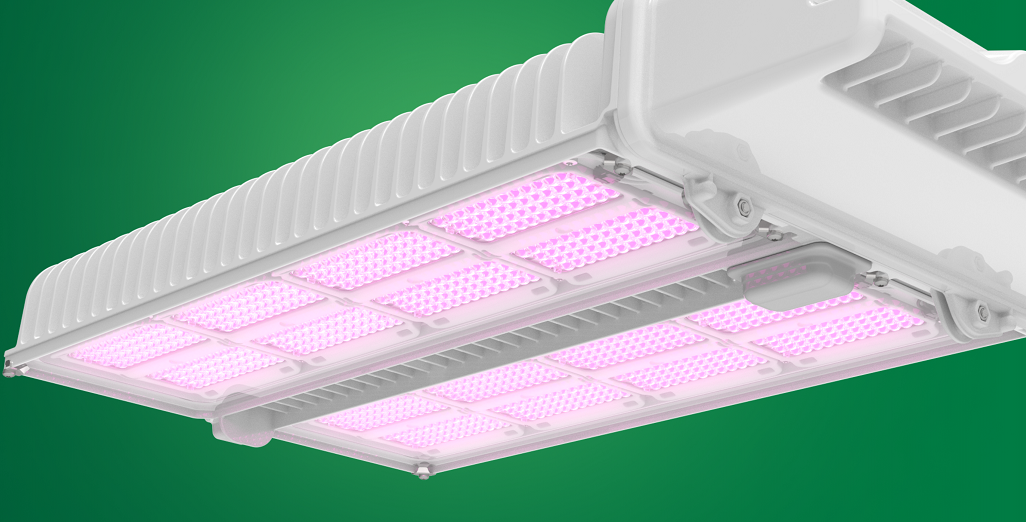

New Philips GreenPower LED toplighting force 2.0

Condensation re-visited

Philips GrowWise Research Center to test and showcase intelligent lighting