Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Feb 2022

Gus and Helma Sonneveld passion to produce premium quality Cymbidiums

Cymbidium industry has declined over the last 10 years, but Joshua Cymbidiums is still operating successfully

The heading is a wee bit of an oxymoron, how can an industry be in decline but still be making a good return? My answer to follow:

Gus and Helma Sonneveld are the proud owners of Joshua Cymbidium, which grows one hectare of cut flower orchids, for international markets. They are situated in Pukekohe on the edge of the Waikato and Auckland border. They have a modern high-tech growing operation, which they have heavily invested in over the years. The glasshouse, built by Apex Greenhouse, has all the modern technology cymbidium orchids require to grow premium quality.

The New Zealand market exports approximately 90% of these cut flowers, predominantly to the US and Australia and Japan. Gus said during the peak of the industry, 10 years ago approximately 300,000 boxes of orchids were exported but now it would sit annually at 120,000 boxes. Gus, born in the Netherlands, has been growing, in New Zealand, for over 30 years together with his brother Joe. Joe is running a .85 ha property in Drury. Gus and Helma built the Pukekohe property in 2011 and have focussed on the mid and late season production where Joe has focussed on the early varieties. This has meant that Joshua has been able to supply their customers from the start to the end of the season. Between the two sites there are 2 full time workers and 16 seasonal staff are required during the height of the season in winter.

Gus estimates there are approximately twenty cymbidium growers left in New Zealand, a considerable drop from a high of approximately one hundred or more in the past. As far as volume goes there are now only four growers of substantial size left.

The industry in New Zealand is worth around ten million dollars in export revenue. What I love about this is that it brings export earnings directly into New Zealand, creating jobs that otherwise would not be there. It also shows that even with Covid and strong overseas competition if you have the best growing facilities, with the most efficient mechanical systems to reduce labour costs, then you will be successful. I believe this is why Gus and Helma have been so successful, they are and will remain to be profitable – because they have invested in the best facilities required for optimum production and therefore returns. If you don’t reinvest and keep up with modern trends you will eventually drop away.

The very first thing I noticed was how clean and tidy this operation was – it is as good as any I have seen. I visited when the plants were not flowering but as new spikes are starting to appear. This is a critical phase as it directly impacts on the outcomes later in the year when harvest begins.

Covid has hit the business like most – interestingly Gus said that many international casinos, who purchased the large cut flowers for display purposes, had in some cases stopped – due to covid restrictions on those casinos operating. It is quite amazing the effects on sales have been when you think of funerals, weddings and other big events down sized or cancelled.

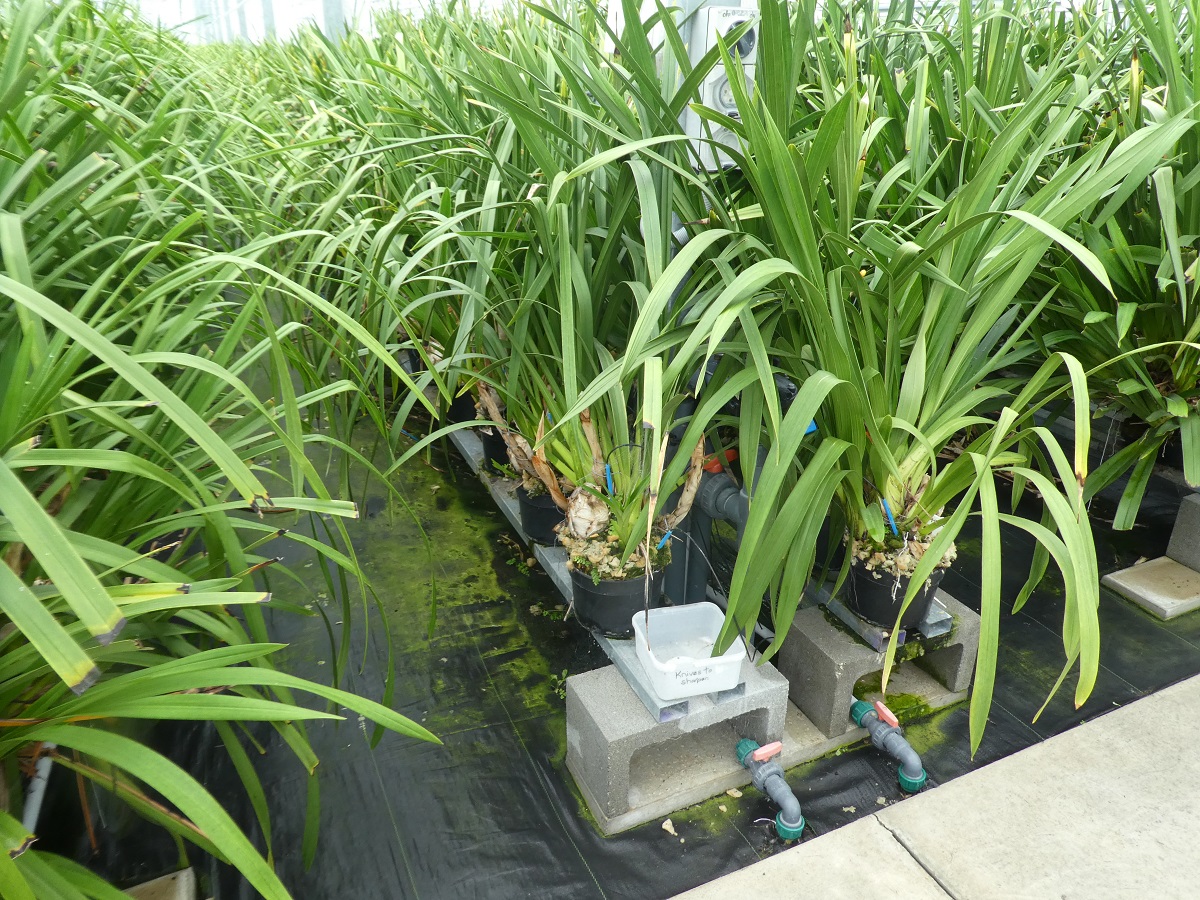

New varieties are generally grown from tissue culture – this is the best way to generate even growth.

New varieties are generally grown from tissue culture – this is the best way to generate even growth.

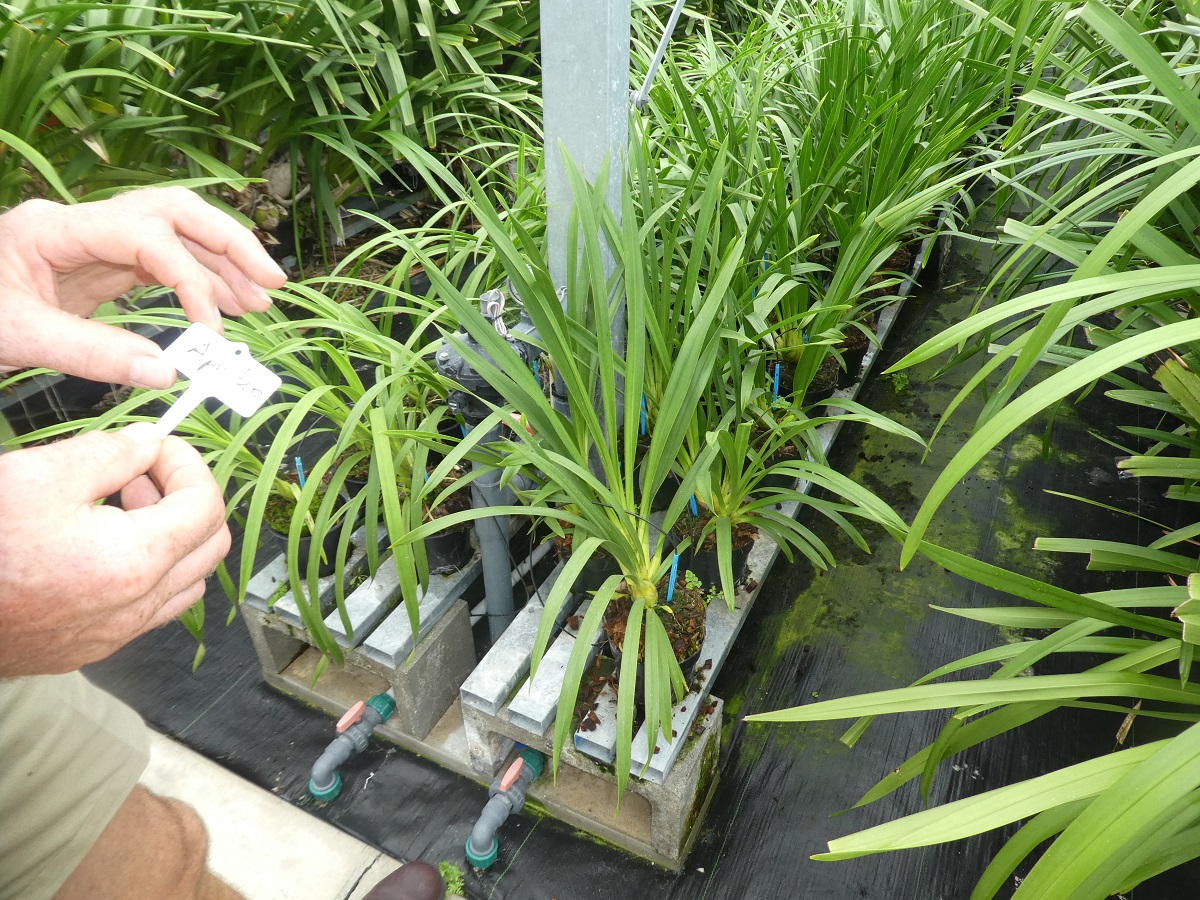

Gus has used a mixture of substrates including coir and stone-wool mix. With having so many different aged plants within one irrigation zone, it makes it difficult to not over water younger plants and underwater older more substantial sized plants. Multiple drippers, per container, are used to help balance this but this takes time and effort to achieve even application. Gus has multiple irrigation collection stations that check his run in and run off. This constant monitoring is necessary to not waste precious resources but to also help maintain the correct water contents.

Gus has used a mixture of substrates including coir and stone-wool mix. With having so many different aged plants within one irrigation zone, it makes it difficult to not over water younger plants and underwater older more substantial sized plants. Multiple drippers, per container, are used to help balance this but this takes time and effort to achieve even application. Gus has multiple irrigation collection stations that check his run in and run off. This constant monitoring is necessary to not waste precious resources but to also help maintain the correct water contents.

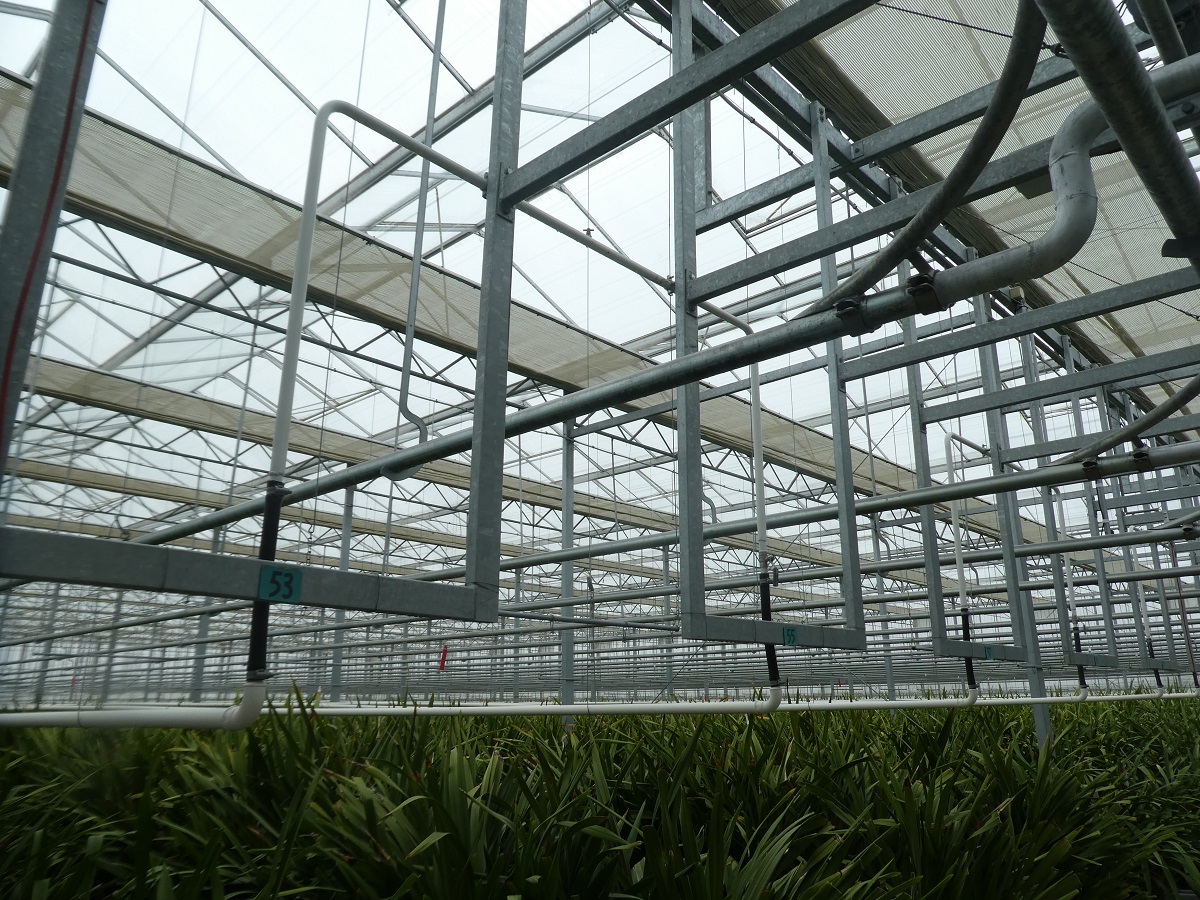

Climate screens are mainly used for control of light levels and plant temperature in the summer (not to high). They also have some energy savings in the winter and help with the humidity and plant temperature (not to low). There is also a pipe rail system used to transport the cut flowers directly to the packhouse. This is also used to remove excess leaf and weeds. The efficiency is huge and makes the work far easier to complete.

Climate screens are mainly used for control of light levels and plant temperature in the summer (not to high). They also have some energy savings in the winter and help with the humidity and plant temperature (not to low). There is also a pipe rail system used to transport the cut flowers directly to the packhouse. This is also used to remove excess leaf and weeds. The efficiency is huge and makes the work far easier to complete.

The grow pipes/heating tubing is kept very close to the top of the plants and when they are flowering, they help control fungal issues that can ruin the flowers – this is a crucial part of the operation and maintaining the very highest flower quality.

The large pack-house makes the process of packing easy and efficient.

The 1.5MW boiler can heat a further one ha. The requirements of minimum 10 degrees and with the aid of the energy/shade screen mean the cost of heating and use of energy is kept to a minimum. The grow pipes are the key to reducing fungal pressures.

The 1.5MW boiler can heat a further one ha. The requirements of minimum 10 degrees and with the aid of the energy/shade screen mean the cost of heating and use of energy is kept to a minimum. The grow pipes are the key to reducing fungal pressures.

If you want to see some beautiful colours check out this article posted in 2020 also with additional information.

https://taurangaorchids.wordpress.com/2020/08/04/joshua-cymbidium/>

“Success is not about how much you earn but more about being content with what you have” Gus Sonneveld. (cover photo)

Article written and compiled by Stefan Vogrincic

All Article’s checked and edited by Marie Vogrincic

I appreciate your comments. Please feel free to comment on the grower2grower Facebook page:

CLASSIFIED

Photo

Gallery

Subscribe to our E-Zine

More

From This Category

Powerplants and RTF Climate Announce Strategic Partnership for the APAC Region

Local florist amongst impressive young horticulturists competing in Karaka

Toasting Tahryn, 2023 Young Horticulturist finalist.

Renee reaps rewards of career switch – now off to Young Horticulturist finals.

Meryn Whitehead, finalist for the 2023 NZ Young Horticulturist competition