Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Feb 2020

Know-How

Eliminate stress from your crops this summer

Plants really like being in a uniform environment. Any stress reduces production or results in a loss of quality. Coatings help you achieve a steady crop growing environment.

“It has been an extremely good summer season for growing greenhouse crops in most parts of New Zealand, almost too good. I have witnessed that several crops have aged faster than they should have. Next season I want growers to understand the benefits of how and when to apply Redusytems greenhouse coatings, which I believe may have the effect of enhancing production and quality of production”. (Stefan Vogrincic)

The hot summers in recent years clearly show that excessive stress leads to many problems for vegetable crops. Poor fruit setting, blossom-end rot, lower production, viruses and growth disorders.

Coatings can play an important role in preventing, or in any event significantly reducing this. To determine the right coating, it is important to first analyse the problems. Often people think there is too much light, but just as often the problem is too much heat.

Be mindful of light levels

Vegetable crops are capable of effectively converting a large amount of light into production. It takes a lot before there is too much light. However, there may very well be light damage. In these exceptional cases, too many free radicals are created. These are harmful substances that destroy the cells and DNA.

However, the plant is not defenceless. If the radiation becomes excessive, the foliage protects itself against this. This temporarily reduces the rate of photosynthesis. When the radiation declines, the foliage reverts to its original condition and once again functions normally.

Especially the plant’s tips may suffer from the foliage’s immune reaction or from real light damage. The solution: use a diffuse coating to better distribute the light within the crop: ReduFuse or ReduFuse IR.

Heat stress

Heat stress occurs far more often than light stress. This inhibits photosynthesis, as well as the activity of enzymes and proteins. The latter can cause a lot of annoying problems. This not only adversely affects the product’s quality, the plant’s resistance also declines. This is why diseases and plagues have a much greater chance of developing in such situations of stress.

Heat stress occurs when the greenhouse temperature rises too high, although it can happen well before this. This is because a high level of radiation raises the plant’s temperature, which can be several degrees higher than the temperature inside the greenhouse. This means that heat damage can already occur, even though you would not expect this to be the case on the basis of the air temperature measured inside the greenhouse.

Evaporation

The crop normally cools itself through evaporation. However, when the temperature is too high, the supply of moisture cannot keep up with the rate of evaporation. The leaves then go limp. To prevent even worse damage, the stomata close up. But this causes the leaves’ temperature to increase even further. Photosynthesis comes to a halt as carbon dioxide is no longer coming in. This halts the production of enzymes and proteins, causing the leaves to function less effectively. Blossom-end rot occurs and leaf edges burn because calcium is no longer being supplied as part of the water flow. This can cause parts of the crop to completely dry out. This situation must therefore be avoided.

The crop’s heating for the most part can be attributed to infrared light, also known as heat radiation. Not all of this radiation is required for photosynthesis and therefore there is no reason why the excessive heat should not be shaded using ReduHeat or ReduFuse IR.

Seeking a balance

The trick in vegetable growing is to make use of the sunlight as much as possible, while at the same time avoiding any damage. Traditionally, vegetable growers in a hot climate are accustomed to shade a significant portion of the light to be sure. However, this is at the expense of production.

Fine-tuning is possible in all instances through the use of the right coating or – as we are seeing increasingly more often – a combination of coatings. By distributing the beneficial light within the crop with a diffuse coating (ReduFuse or ReduFuse IR). By preventing excessive heating of the crop by reflecting heat radiation (infrared light) with ReduHeat or ReduFuse IR. And if it cannot be avoided, it is possible to partially reflect the PAR light (which is required for photosynthesis) with ReduSol, if necessary in combination with SprayChalk.

For more information:

ReduSystems®

sales@redusystems.com

www.redusystems.nl

Mardenkro products are distributed by Horticentre Group in New Zealand

CLASSIFIED

Subscribe to our E-Zine

More

From This Category

Ground cover: woven weed mat or solid plastic… or both?

Integration of Philips GrowWise control system with climate computer allows Huisman Chrysanten to light more effectively and efficiently

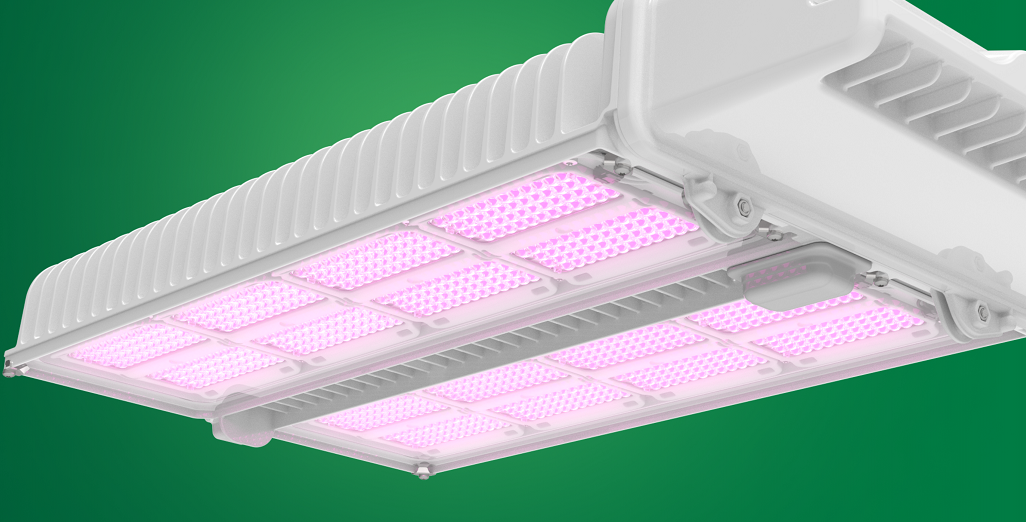

New Philips GreenPower LED toplighting force 2.0

Condensation re-visited

Philips GrowWise Research Center to test and showcase intelligent lighting