Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Jun 2020

Look back to move forward

Steering a crop becomes less guess work and more certain with data

Experience is crucial when making changes to your crop at this time of the season. Winter is here and its only 3 weeks from the shortest day. Covid-19 has been a massive disruptor this season and unless you have a regimented growing approach then issues may arise, not un-expedited but definitely not wanted.

Balancing current crop load is a judgement call made on a range of factors including growing decisions applied in recent months. What you have right now would determine how I advise on the short- and medium-term future. Light levels a major factor. With different greenhouse structures, heating and irrigation systems make every approach unique. The age of plants and different cultivars are key in the decision making as well.

Crop registration, for myself and thousands of other growers around the world, is by far and away the best method to use. Current data compared to a real time visual study of the crop to advise on the growth strategy for the short term with an eye on the next few weeks and months. I am keeping a close eye on the artificial intelligence vs grower – autonomous greenhouse challenge you may be aware of. I am a big fan of AI and the potential advances and sustainability it will offer growing systems.

I get very excited with what the future holds and love new ideas and technology. I know NZ growers would do much better with the technology available from around the globe, however, business cases need to stake up return on investment (ROI).

While I wait for all of the next generation of growing tools (Grow lights, improved heating, dehumidification, screens, irrigating from sensors etc) I will always continue to look back at old crop registrations to see what has or hasn’t worked and try to build on the successes. Of course, not making the same mistake twice is paramount. Looking back is not about going backwards, for me it is about progressing forward. From an advice point of view utilising every piece of light, to grow maximum yields, balanced with the cold hard facts of returns is my goal. Every environment is heated, this can be dropped or increased based on the crop load/plant vigour. Not enough fruit load may require using more energy, conversely extreme fruit load will require reducing energy giving opportunity to the winter ills and chills. You can’t add produce but you can take it off is another adage but by the time a fruit has been developed it has used precious energy that could have been redirected. Manipulating fruit size is a way to redirect energy either way but this has limits.

This week, and the reason I am writing this article is because of a crop report I received from a grower. The report was excellent and it was very hard to decide how much or if any the crop should be moved left or right or whether it stayed on the same path. Having multiple years of data for this crop, which has the same variety and planting date, makes it so much easier to plan, as it did in this case. It could also make me redundant 🙂

I appreciate your comments. Please feel free to comment on the grower2grower Facebook page:

https://www.facebook.com/StefanGrower2grower/

Article Written and compiled by Stefan Vogrincic, Consultant, Grower2Grower

Article Edited by Marie Vogrincic, Editor, Grower2Grower

CLASSIFIED

Subscribe to our E-Zine

More

From This Category

Ground cover: woven weed mat or solid plastic… or both?

Integration of Philips GrowWise control system with climate computer allows Huisman Chrysanten to light more effectively and efficiently

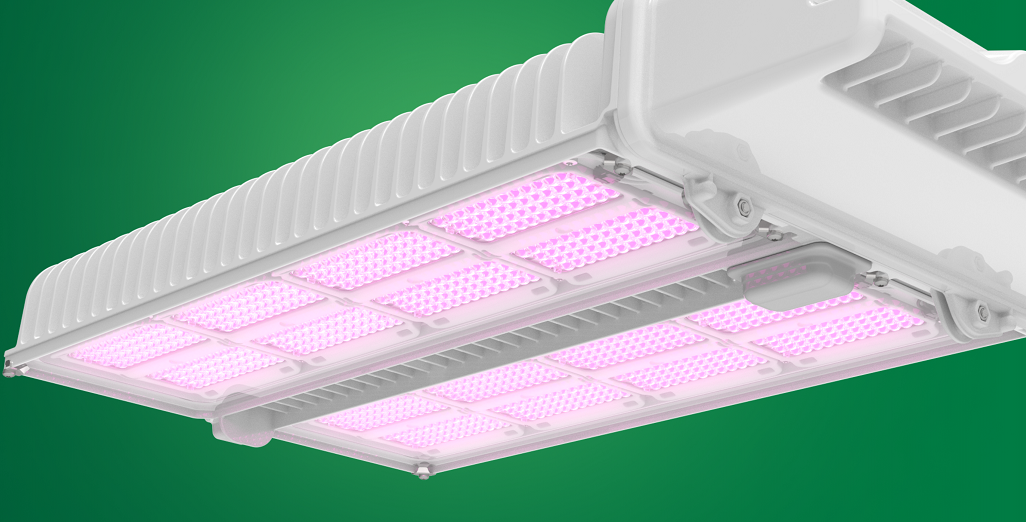

New Philips GreenPower LED toplighting force 2.0

Condensation re-visited

Philips GrowWise Research Center to test and showcase intelligent lighting