Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Nov 2021

PepMV Update

Summer key

For tomato growers that have been infected with the Pepino Mosaic Virus (PepMV) the next three to four months will be a key period to observe the effects during high light levels and naturally increasing temperature. Recently I was fortunate to be part of a meeting with experienced growers and virus experts in England, I was interested to learn how different factors, such as age and variety of crop, will affect production and fruit quality.

For plants already infected and under a high fruit load it will be important to observe how they cope with several days of bad weather or intense temperatures. I am interested to find out if normal whitefly levels make it increasingly more challenging to maintain vigour while the plant has PepMV. On a recent visit to a site, that was identified in autumn as having PepMV, the crop was still producing with minimal symptoms, the leaves on the plants had less curling compared to the middle of the winter. This is a cherry crop so the actual weight on the plant from the fruit is much lower than a standard large round.

Information collected and shared by growers will be the best way to understand the impacts from the virus. I hope from gathering this information we would, as an industry, plot a strategy for best practice to combat PepMV. If we don’t document the actual physical impacts then it will make it difficult to provide the best possible decisions for the entire commercial tomato growing industry.

The main message I ‘took home’ from the video meeting, with the overseas experts, is inoculation strains were the most effective way to mitigate the negative impacts from the virus. Even though the English growers were weary when the inoculation was introduced, as it was unknown how it would react (or possibly mutate), it proved to be both effective and not have adverse effects. This does not mean the exact same scenario wouldn’t occur here but this is basis for why I believe the sooner we work alongside government agencies and use quarantine facilities to start carrying out tests, the sooner we could have a safe option available if or when we might require it. To do nothing is simply to do nothing and, in my view, would be a mistake that may come back to bite our growers in the backside. Even if it is proven we will not require inoculation or the inoculation strain could pose a risk if released, I would gladly support industry funding this process.

With new crops about to be planted please make sure you have a deep clean between crops. I suggest products such as Virkon and Hydrogen Peroxide. Cleaning foams would also be useful. If you can have your greenhouse empty for three weeks and remove all of the organic material from your greenhouse you may have a chance of eliminating the issue naturally. This will not be practical for most operations that work on short crop turn arounds.

Article written and compiled by Stefan Vogrincic

All Article’s checked and edited by Marie Vogrincic

I appreciate your comments. Please feel free to comment on the grower2grower Facebook page:

https://www.facebook.com/StefanGrower2grower/

CLASSIFIED

Subscribe to our E-Zine

More

From This Category

Ground cover: woven weed mat or solid plastic… or both?

Integration of Philips GrowWise control system with climate computer allows Huisman Chrysanten to light more effectively and efficiently

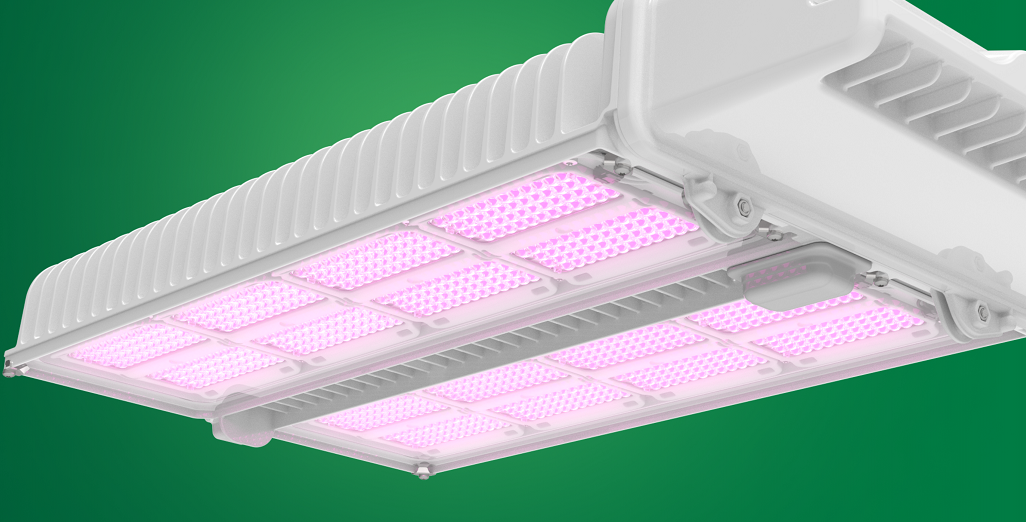

New Philips GreenPower LED toplighting force 2.0

Condensation re-visited

Philips GrowWise Research Center to test and showcase intelligent lighting