Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Feb 2024

Robots to make banana processing more a-peeling

“Workforce challenges, supply chain issues, and disease threats all contribute to the need to find innovative production approaches”

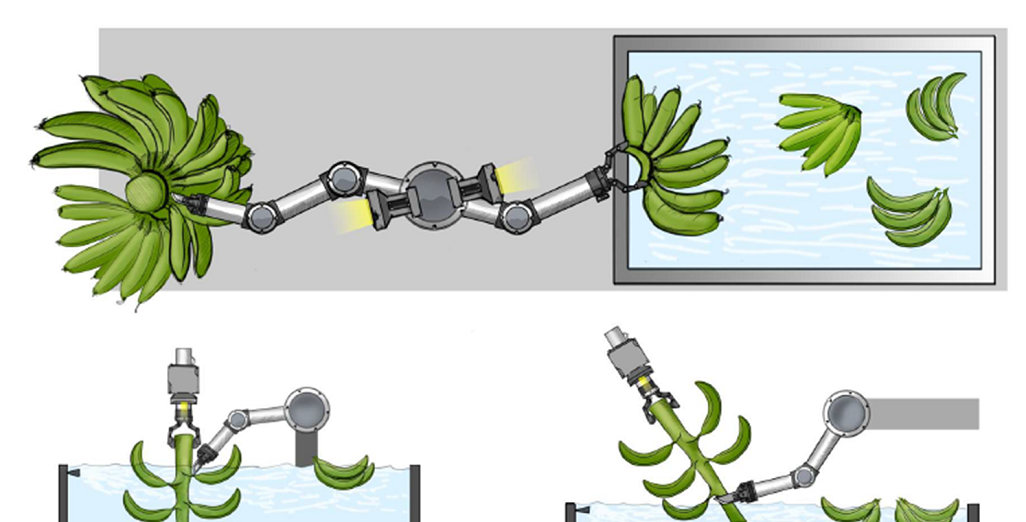

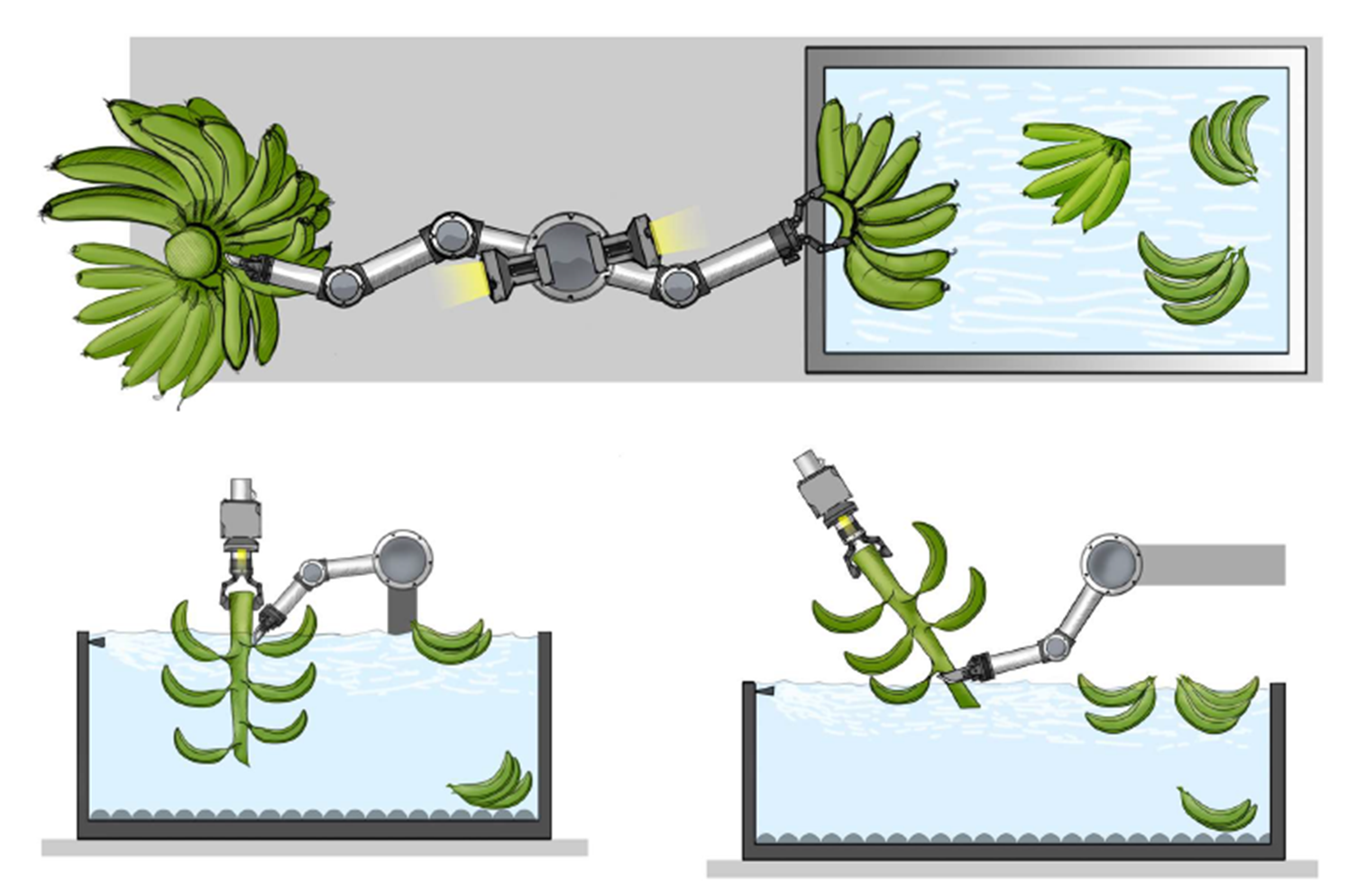

Scientists are researching and developing new technology to build a prototype robot arm that will automate the repetitive and intensive parts of banana processing, resulting in significant efficiencies for the banana industry.

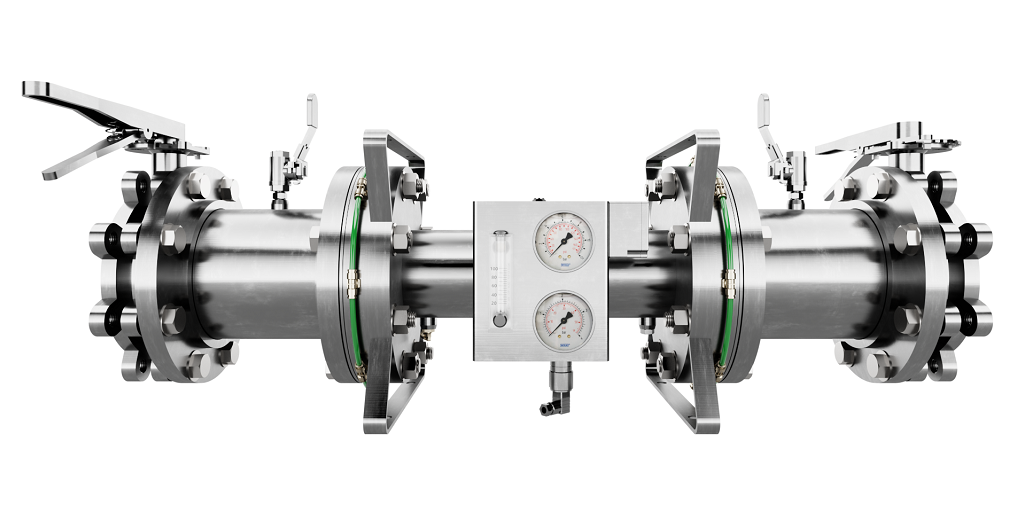

Delivered through Hort Innovation and led by QUT in collaboration with Future Food Systems, the Advanced Robotics for Manufacturing (ARM) Hub and BNL Industrial Solutions, the $2M program will use technology such as computer vision and machine learning to provide the banana industry with a solution for the process known as banana ‘de-handing’.

Banana de-handing is the process of separating the banana fruit from the stalk and it is a repetitive and physically demanding activity that if automated, could improve processing efficiencies and provide a valuable integration point for robotics systems.

Hort Innovation chief executive officer Brett Fifield said investing in emerging technology to make production easier is a key priority.

“Workforce challenges, supply chain issues, and disease threats all contribute to the need to find innovative production approaches,” Mr Fifield said.

“If successful, this type of technology could also be applied to other crop-types to support Aussie fruit and vegetable supply.

QUT lead researcher Dr Chris Lehnert said commercialisation is the goal.

“Over the next two years we will build the prototype robot for banana de-handing and then integrate that robot with a vision system that allows it to ‘see’ what actions it needs to perform, “Dr Lehnert said.

“The prototype will then be trialled at the ARM Hub’s testing facility where we will conduct further testing and allow growers and potential investors to come and see it action.”

Australian Banana Growers’ Council chief executive officer Leanne Erakovic said the banana industry was keeping a close eye on the project.

“Currently there is no commercially-available solution for the banana industry,” Ms Erakovic said.

“Banana de-handing is a core process in all banana packing sheds, so any efficiencies that could be realised through the use of robotic technology would likely have a significant impact on growers’ processing costs. A win-win for our industry and for consumers.

“This technology has great potential to fulfil a task that is notoriously hard to resource, as it requires time and specific skills. On top of that, it could reduce manual handling fatigue and won’t impact overall job availability on-farm.”

Bananas are one of Australia’s most loved fruits with 91 per cent of Australian households buying bananas in 2022/23 according to Hort Innovation’s recently released 2022/23 Australian Horticulture Statistics Handbook. On average, each Australia consumes 14.2 kilograms of bananas each year.

Article Source: www.horticulture.com.au

CLASSIFIED

Photo

Gallery

Subscribe to our E-Zine

More

From This Category

Minipack Quickshrink Ltd.

John van Santen joins the management of Metazet

Metazet Completes Greenhouse Installation in 2 Days for New R&D Greenhouse

Bale Breaker, Just Press Play

Introducing Moleaer’s Trinity: Revolutionizing Agriculture with Advanced Nanobubble Technology