Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Jun 2020

Spray damage on plants, is it too common?

TEST in different conditions

Far too often I see damage associated with spraying. More and more natural based products are being used to control pests, which is very encouraging because it demonstrates grower’s willingness to use less chemicals. The issue I find is that under different greenhouse conditions, the reaction on the plants and fruit using some products may be detrimental.

I made a mistake, many moons ago, applying an oil-based product during winter. It did not dry fast enough and hence I believe this was the probable cause of the damage that my fruit sustained. I had used the product before and not experienced any fruit quality issues. I also had a good reduction of the target pest. However, with the later application, in winter, I noticed small speckling on the fruit, approximately two to three days later, the damage had affected one/two trusses per plant. Even though this was a ‘natural based’ product I was not able to sell the produce as first grade fruit, with some having to be dumped.

In recent weeks I have come across crops with damage (see pic). This damage is preventable. We can all get advice from the supplier and follow the label on how to best apply different products, but do this with caution and be aware there may be risks.

I sincerely urge growers to trial any new products, on a handful of their plants, applying in the morning and afternoon, on both sunny and cloudy days then wait several days to see if you notice any harmful effects before deciding to spray entire crops. If you use the product in March, with no issue, please don’t assume there won’t be an issue in June. Greenhouses are not laboratories; however, growers make the best scientists. Once you are comfortable with how a product works best in your environment then the chance of damage is minimal.

Too often a product may deliver a poor result, which put growers off using, what is likely a very good product used in the correct circumstances, again. I have never had, or blamed, poor advice from suppliers if a mistake was made, it was invariably poor judgement on my part. No one is perfect, by spending a little bit of extra time, testing a product, it may prevent you having a much larger headache to deal with and you will reap the benefits of the product.

Some factors to consider when applying new products at different times of the year:

- Weather conditions (sunny or cloudy at time of application)

- Temperature

- HumidityTime of Application

- Application rate

- Drying time

- PH levels required for water/spray mix

I appreciate your comments. Please feel free to comment on the grower2grower Facebook page:

https://www.facebook.com/StefanGrower2grower/

Article Written and compiled by Stefan Vogrincic, Consultant, Grower2Grower

Article Edited by Marie Vogrincic, Editor, Grower2Grower

CLASSIFIED

Subscribe to our E-Zine

More

From This Category

Ground cover: woven weed mat or solid plastic… or both?

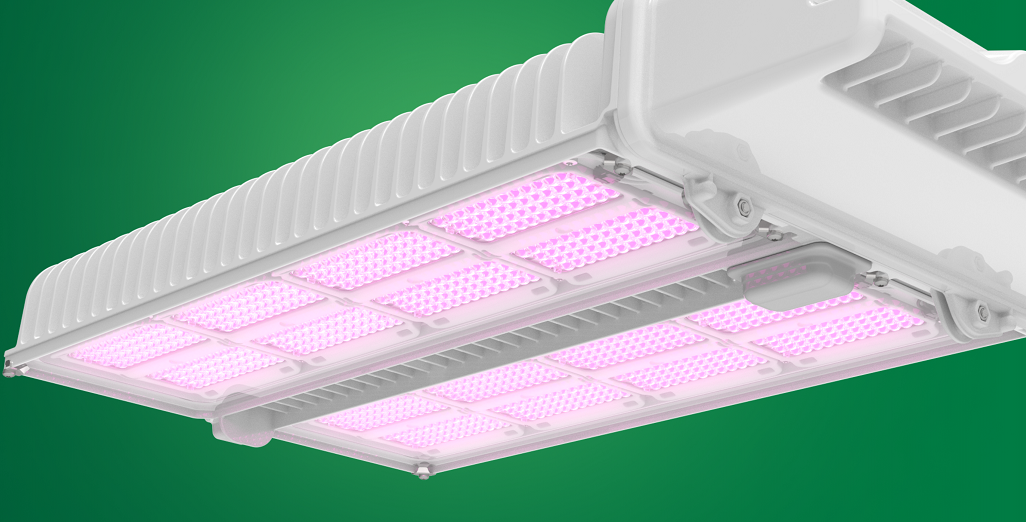

Integration of Philips GrowWise control system with climate computer allows Huisman Chrysanten to light more effectively and efficiently

New Philips GreenPower LED toplighting force 2.0

Condensation re-visited

Philips GrowWise Research Center to test and showcase intelligent lighting