Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Aug 2025

The Rise of Plant-Driven Irrigation

What if plants could tell us exactly when and how much water they need?

Insights from a Vivent specialist! What if plants could tell us exactly when and how much water they need? In this interview, Andrzej Kurenda, Chief Science Officer at Vivent Biosignals, shares how plant-driven irrigation works, why it’s a breakthrough for sustainable agriculture, and how it’s transforming water use, crop yields, and cultivation strategies. Welcome to the future of agriculture, where plants lead the way!

Q: How does plant-driven irrigation work?

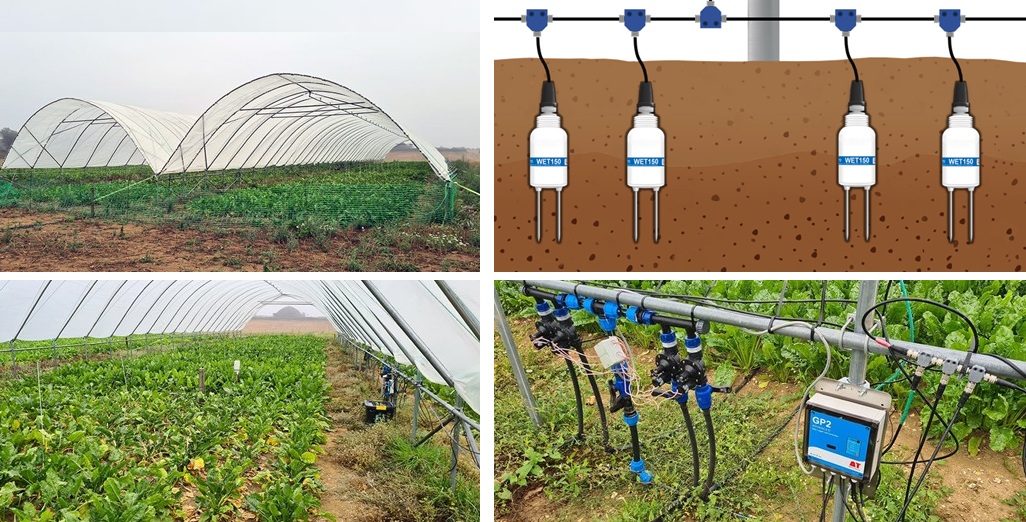

A: “Plant-driven irrigation uses Vivent’s biosensors, attached directly to plant stems, which detect electrical bio-signals that reflect the plant’s internal responses to all sorts of stimuli, including water stress. These signals are interpreted by predictive drought models, which trigger irrigation only when groups of plants show actual signs of needing water. A rule-based system translates model output into actions, activating irrigation through relay controllers when plants demand water.”

Q: What’s the difference between Vivent Biosignals’ irrigation solutions and others?

A: “Most other systems rely on environmental proxies, like soil moisture or climate conditions, while this approach measures the plant itself. That distinction allows irrigation decisions to be based on what the plant actually experiences, not on assumptions derived from external factors.”

Q: What’s the most surprising thing you’ve seen in plant-driven irrigation trials?

A: “Plants sometimes didn’t request water for an entire day, or demanded it at unexpected times, like late at night, challenging conventional irrigation patterns and proving how dynamic real plant needs can be.”

Q: Is this technology suitable for all crops and growing systems?

A: “Yes, the underlying models can be applied across a wide range of crops and environments. While some adaptation is needed for different crop types, the fundamental approach has been successfully tested in vegetables, herbs, and ornamental plants.”

Q: How quickly can a grower start seeing meaningful results?

A: “In some situations, visual improvements — such as more and larger fruits — were noticeable during the production phase. However, measurable benefits depend on the crop and conditions. Earlier indicators may be available with further analysis, but results generally become clear during fruit development.”

Q: What impact does it have on water use, plant stress, or yield consistency?

A:“The system has the potential to save water by delivering exactly what the plant needs—no more, no less, when the plants need it. Even when the total volume doesn’t decrease, the timing of irrigation can be optimized to align with plant demand, reducing crop stress and improving consistency in growth and yield. We have seen in our initial pilots that yield in cucumbers, tomatoes, and flowers increases by more than 10%.”

Q: Do growers need technical expertise to work with it?

A: “At the current stage, some technical understanding is needed, especially for growers who want to manage the system independently. However, efforts are underway to simplify the interface and create a fully automated experience that requires minimal intervention.”

Q: What does a typical day look like for a grower using Vivent plant sensors to guide irrigation?

A: “In trial settings, most growers don’t need to take action—irrigation runs autonomously. Some do check dashboards daily to compare drought predictions with other sensor data or to understand trends. While not required, the system provides useful insights that engaged growers often explore.”

Q: How scalable is this across multiple sites or crops?

A: “The technology is scalable. The models are flexible and can be calibrated for new crops or environments. The main scalability challenges lie in hardware integration and operational logistics, not the models or system themselves.”

Q: Where do you see plant-driven irrigation in 5 years?

A: “The goal is full automation. In five years, the system could be plug-and-play, integrated into larger farm management platforms, and capable of managing water—and potentially other inputs—autonomously and in real time, with minimal manual oversight. This of course means we will have built long term relationships with users and they will have full confidence in the system.”

Q: What’s your message to growers or companies who are still hesitant?

A: “This system gives water exactly when the plant asks for it, helping growers respond more naturally and precisely to plant needs. It can reduce the time and stress of managing irrigation, and in time, may also lead to better yield and resource efficiency.”

Learn more HERE

Article Source HERE

CLASSIFIED

Photo

Gallery

Subscribe to our E-Zine

More

From This Category

The Rise of Plant-Driven Irrigation

The BBRO Tackles Drought Risk in Sugar Beet Production

Botrytis Alert: Key Strategies to Minimize Losses

(Best of 2024) Fleecegrow turning wool into substrates a reality

Less fertilisation and higher yields with Ambiorix iron polyphosphate