Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Jul 2022

Tomato grower eyes innovative workaround after CO2 shortage cuts production 20%

NZ Gourmet production director Roelf Schreuder is banking on patented waste wood gasifiers to reverse a drop in its harvest caused by the country’s carbon dioxide shortage.

Republished/linked with the permission of Tom Pullar-Strecker

MORE FROM

TOM PULLAR-STRECKER • SENIOR BUSINESS JOURNALIST

tom.pullar-strecker@stuff.co.nz

One of the country’s largest fruit and vegetable growers, New Zealand Gourmet, hopes it has found a workaround after a nationwide shortage of commercial carbon dioxide supplies cut the production of tomatoes at its 12 hectare site near Taupo by about 20%.

And it is a solution that could help a technology start-up on its way to export success.

NZ Gourmet is the latest big food producer to report fall-out from the carbon dioxide shortage, which is also threatening to interfere with the production of craft beers and supermarket-packaged chicken.

Its facility in Mōkai, north of Taupō, is unusual in that it uses geothermal energy instead of coal or gas boilers to heat its greenhouses and sustainably produce tomatoes and peppers during winter.

READ MORE:

* CO2 shortage threatens wide range of NZ groceries including Tegel chicken

* Carbon dioxide shortage threatens to take fizz out of craft beer

* Carbon dioxide shortage could add to rising food prices

But production director Roelf Schreuder said the downside of using cheap geothermal energy for heat was that the company needed to obtain about 30 tonnes of carbon dioxide (CO2) each week to optimise growing conditions at the facility.

(image supplied) NZ Gourmet production director Roelf Schreuder is banking on patented waste wood gasifiers to reverse a drop in its harvest caused by the country’s carbon dioxide shortage.

NZ Gourmet had been unable to buy any CO2 since the Marsden Point oil refinery closed at the end of March, Schreuder said.

“This is resulting in fewer tomatoes on the market over the winter period, at a time when fewer tomatoes are already grown due to high energy costs.”

The Marsden refinery had produced carbon dioxide as a by-product of its refining process and the impact of its closure has been exacerbated by production problems at Todd Energy’s Kapuni gas field in Taranaki, which is now the only domestic source of liquid and food grade CO2.

NZ Gourmet is banking on new technology developed by Callaghan Innovation spin-off Hot Lime Labs to get its vines back to full production.

Hot Lime Labs has developed gasifiers that burn wood waste at night, when heat is needed most in greenhouses, but which are optimised to produce CO2, rather than heat, from combustion.

MORE FROM

TOM PULLAR-STRECKER • SENIOR BUSINESS JOURNALIST

tom.pullar-strecker@stuff.co.nz

That CO2 is then stored in “patented limestone pellets” for later release during daylight hours, when it helps promote plant growth through photosynthesis.

NZ Gourmet trialled Hot Lime Labs’ system at its Mokai’s site last year and is expecting its first commercial units later this year.

Hot Lime Labs chief growth officer Tijs Robinson said other growers that relied on gas for heat and CO2 had an incentive to switch to a renewable heat source and a separate supply of CO2 because of the rising cost of natural gas.

Robinson expected its work with NZ Gourmet would also be a step on the way to developing an export market for its gasifiers in the massive Netherlands market, where it is has been seeking distribution and service partners.

“New Zealand has about 500 to 700 hectares of high-tech greenhouses; the Netherlands has 10,000ha to 15,000ha.”

(image supplied)Hot Lime Labs founder Vlatko Materic has just returned from Europe, where the company is recruiting business partners.

Growers in Europe were faced with an urgent need to reduce their reliance on natural gas to produce heat and CO2 in the wake of Russia’s invasion of Ukraine, Robinson said.

“Our chief executive has been in Europe, and he’s been talking to people who are expecting or have already seen gas prices triple.”

Horticulture firms tended to try to keep levels of carbon dioxide in their greenhouse at between 800 and 900 parts per million, which is about double the current atmospheric level of 420ppm, as that increased plant growth by about a quarter, Robinson said.

But without a separate source of CO2, a switch away from fossil fuels to other heat sources would leave them short.

Robinson said Hot Lime Labs regarded its method as sustainable, as it “liberated” carbon dioxide from waste wood where it is commonly regarded as being in one stage of the natural atmospheric carbon cycle.

Energy Minister Megan Woods said “potential impacts” on the CO2 supply chain were canvassed in a Cabinet paper last year, when ministers were considering the closure of the Marsden Point refinery.

But she said retaining the supply of CO2 as a by-product of the refining process had not been a sufficient reason to intervene in the closure.

Click on the link below to read this and related articles

CLASSIFIED

Photo

Gallery

Subscribe to our E-Zine

More

From This Category

Tomato grower applies Tobre after contamination

KWS inaugurates new R&D facility in Uberlândia, Brazil

John van Santen joins the management of Metazet

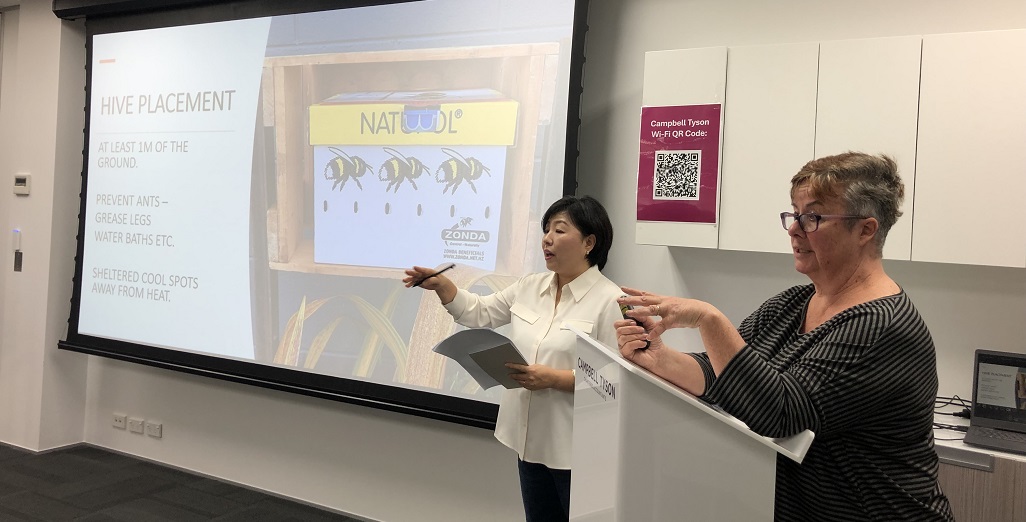

Workshop for Auckland’s Korean tomato growers held last week

Could the Global Boom in Greenhouses Help Cool the Planet?