Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Mar 2022

5 tips for growing with LED

5 tips for growing with LED

- LED is being applied on an increasingly large scale in greenhouses

- A grower should constantly be mindful to realize the right climate- and cultivation conditions for the way in which the LED lighting is being applied.

- Our specialists share their experience and tips on growing with LED.

LED is being applied on an increasingly large scale in greenhouses, for vegetable as well as floriculture crops. Although many crops have already been proven to grow well under 100% LED lighting, a hybrid solution is sometimes chosen as a first step.

When making the (partial) transition to LED the choice can be made for significant energy savings on the one hand, or for raising the light intensity on the other. In both cases, next to selecting the right LED spectrum, you should keep the total cultivation set up in mind to make the transition successful. This includes factors such as plant density, irrigation, and plant variety amongst others. HPS lighting creates radiation heat which LED lighting mostly lacks. The LED modules which are being applied most at the moment have an efficiency of 3,2 to 3,7 µmol light per joule electricity-input, and for HPS, with an efficiency of 1,8 µmol/J, this is 40 to 50% less. Besides the factor of energy savings, this big difference has the advantage that the climate can be controlled better by steering the warmth and light separately. However, consequently you as a grower should constantly be mindful to realize the right climate- and cultivation conditions for the way in which the LED lighting is being applied. Naturally there are big differences between cultivations, but there are several common factors as well. We would love to share what we have learned from experience.

Tip 1: Optimum use of your lighting with dimmable LEDs

Obviously, you will choose an LED spectrum with proven results for your crop. For many crops the light recipe has been developed, and we can select from a database of over 150 proven recipes. When HPS lighting is being replaced (partly) by LED, the total light level in the greenhouse usually increases significantly. In that case especially, it is useful to be able to dim the intensity of the LED lighting: with a dimmable installation you can respond to both the needs of the crop, weather conditions and the energy market, without making concessions to the uniformity of the light. An additional benefit of dimmable LEDs is that these become approximately 10% more efficient when dimmed. This decreases the energy usage per light unit.

Tip 2: Crop activity is the key

Dividing the assimilates created by photosynthesis is an important consideration. It is a pitfall to have the plant absorb all the lighting with an artificial lighting installation, but neglect to create circumstances for the plant to distribute the assimilates to the parts of the plant where we would like them to go, which are often the fruits and/or the flowers. Without taking the appropriate actions the crop could have too little evaporation, the plant temperature could stay too low, or absorb insufficient fertilizers.

Due to the absence of radiation heat, in some cultivations with LED screening is used more intensively and the windows stay closed more often to keep the heat inside the greenhouse. This can lead to a climate which is too passive, where the plant has problems evaporating. There are several options to keep the plant active. Key is the drainage of fluid around the plant. You can also consider extra air movement by fans for example, or by adding a (minimal) heating pipe in combination with a gap in the screen, and possibly leaving the windows slightly open. Active dehumidification by air handling units for example, is also a perfect option in combination with LED lighting. In that way you can actively screen and dehumidify with limited energy input.

In many cases we have seen that the energy saved by lighting with LED should be compensated slightly by a higher input of warmth. How much additional warmth input is needed differs strongly per crop situation, but the net energy savings compared to HPS are considerable when electricity and warmth are added. Moreover, in most situations, warmth also has a lower cost than electricity.

Tip 3: The plant rules

For optimal growth the plant should always be leading. Eventually the crop will show to what level the light offered will be converted into the desired development. Keep an eye on the water absorption, developmental speed, etc. and adjust the climate accordingly to keep the crop balanced. For many crops, in order to make the plant use the created assimilates in the right way, you need to steer more generatively compared to HPS. Consider, for example, realizing a larger DIF, moisture balance, (leaf)pruning strategy, and adjusting the EC or recipe of nutrients where needed. For your crop, a greenhouse temperature of 20 degrees with HPS feels very different to 20 degrees with LED. That means that with LED you should look more at the plant temperature instead of the surrounding temperature. It can also be a good idea to look at the plant temperature for the parts of the plant separately. When heat sources are applied differently this can have influence the temperature of the roots and fruits for example, compared to the head of the plant. An example of this is that in high wire crops the growth tubes are used much more with LED or hybrid lighting, to have a direct effect on the temperature of the fruits.

Tip 4: Control the plant temperature by screening

In many cases we see that growers who have an energy screen next to a shade screen, are more flexible and have more control over moisture and plant temperature compared to growers who only have a screen.

There is a big advantage in using an energy screen to control the plant temperature. Especially growers who are used to lighting with high intensity HPS are not always aware of the effect of the heat radiation from the lights, when the emission from outside is low er even negative. In many cases it could be a good option to close the energy screen almost completely, limiting the emission from the crop to the atmosphere, while air exchange and dehumidification can continue.

Tip 5: Keep calculating based on the light sum

When applying higher light intensities, light will be a limiting growth factor of a cultivation to a lesser degree. Artificial lighting will lead to stabile light sums in winter. Therefore, use the available light sum to create a stabile cultivation guaranteeing continuity. Light becomes less of a bottleneck, especially when warmth and light can be steered separately with LED lighting. This does not mean that you as a grower should not remain aware of the light sums that need to be reached and the growth- or production potential that entails. By realizing plant loads that are too high the crop becomes unbalanced, leading to difficult recovery in winter. Remain aware of a realistic plant density, harvest weight, harvest stage and pruning strategy.

How to make a successful LED cultivation

More and more growers make the switch to energy-efficient LED lighting and become convinced of the possibilities. To make the most of the potential, there are a number of ‘buttons’ to push to get the most out of your crop. Think of more than just the light, but of all growth factors in the greenhouse and let the plant guide you in your decisions.

Leontiene van Genuchten is a plant specialist for floriculture at Signify. She is a practical researcher in heart and soul with an eye towards meeting the needs of growers. Since she began working at Philips Lighting in 2015, Leontiene has been collaborating with researchers and growers to develop and improve LED lighting technologies that are in floriculture.

Leontiene van Genuchten is a plant specialist for floriculture at Signify. She is a practical researcher in heart and soul with an eye towards meeting the needs of growers. Since she began working at Philips Lighting in 2015, Leontiene has been collaborating with researchers and growers to develop and improve LED lighting technologies that are in floriculture.

Erik Stappers is a plant specialist for vegetables at Signify. His focus is on high-wire crops and leafy greens. Erik is closely involved in projects in Western Europe and works together with the growers to create the optimal solution

Learn more about how our horticultural LED lighting can benefit growers around the world and visit our webpages.

For further information, please contact in New Zealand:

Graeme Neale

Business Development Manager

Specification, Systems and LED Agriculture Solutions

Mobile + 64212254526

Email graeme.neale@signify.com

Level 3, 123 Carlton Gore Road,

Newmarket, Auckland 1023

A carbon neutral company

International

Global Marcom Manager Horticulture at Signify

Daniela Damoiseaux

Tel: +31 6 31 65 29 69

E-mail: daniela.damoiseaux@signify.com

About Signify

Signify (Euronext: LIGHT) is the world leader in lighting for professionals and consumers and lighting for the Internet of Things. Our Philips products, Interact connected lighting systems and data-enabled services, deliver business value and transform life in homes, buildings and public spaces. With 2020 sales of EUR 6.5 billion, we have approximately 37,000 employees and are present in over 70 countries. We unlock the extraordinary potential of light for brighter lives and a better world. We achieved carbon neutrality in 2020, have been in the Dow Jones Sustainability World Index since our IPO for five consecutive years and were named Industry Leader in 2017, 2018 and 2019. News from Signify is located at the Newsroom, Twitter, LinkedIn and Instagram. Information for investors can be found on the Investor Relations page.

CLASSIFIED

Photo

Gallery

Subscribe to our E-Zine

More

From This Category

Integration of Philips GrowWise control system with climate computer allows Huisman Chrysanten to light more effectively and efficiently

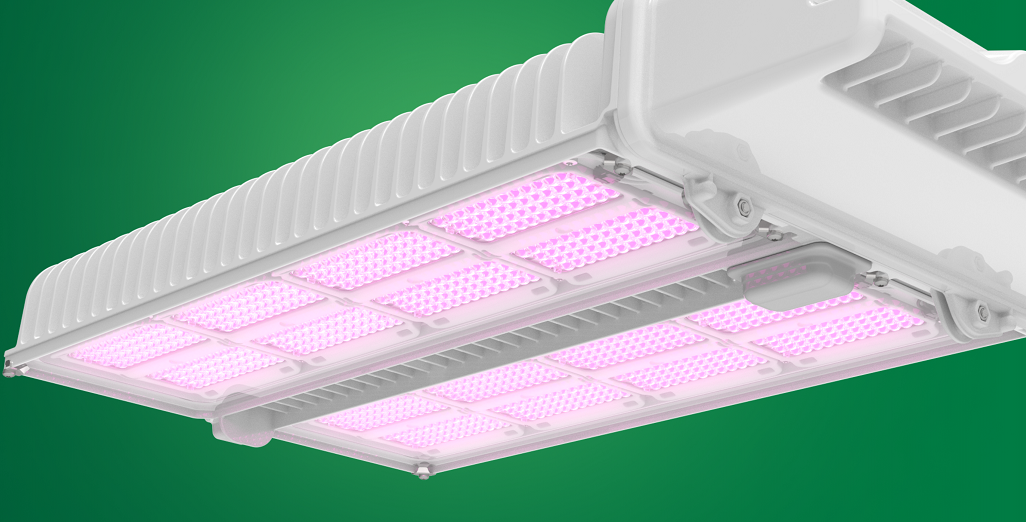

New Philips GreenPower LED toplighting force 2.0

Philips GrowWise Research Center to test and showcase intelligent lighting

Can you grow cut chrysanthemums using only red light?

Signify foresees a bright future for vertical farming, driven by automation and diversification.