Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

What cultivation methods do you employ? Options for enhanced rising and production efficiency:

In the early years of growing without daylight, most of the attention was on the development of leafy crops like lettuce, herbs and microgreens. These crops have a fast turnaround time, high harvest efficiency, require relatively little labor to grow, so it is easier to automate their cultivation. In recent years, there has been more and more interest in soft fruits, such as strawberries, and a great deal of attention has been paid to dwarf varieties of, for example, tomatoes and sweet peppers. But what other possibilities are there for indoor farming? And how can this technology be applied to improve the crops in greenhouses or fields?

A strong start for fast and uniform growth in lettuce

One of the most important growth phases for plants is their start: the raising from seed to young plant material. This crucial foundation can make or break a crop, with consequences for both growers and retailers, as well as food processors. Increasingly we are seeing the impact of changing weather conditions on the availability of products on supermarket shelves. More control over the plant raising phase may help reduce risks in cultivation and improve the results. Grafting tomatoes in the middle of summer has become challenging due to the high temperatures, while growing lettuce plants in winter can easily take up to 60 days. When the starting phases take place in a climate-controlled environment without exposure to daylight, growers can provide an optimal product year-round, without the weather impacting it.

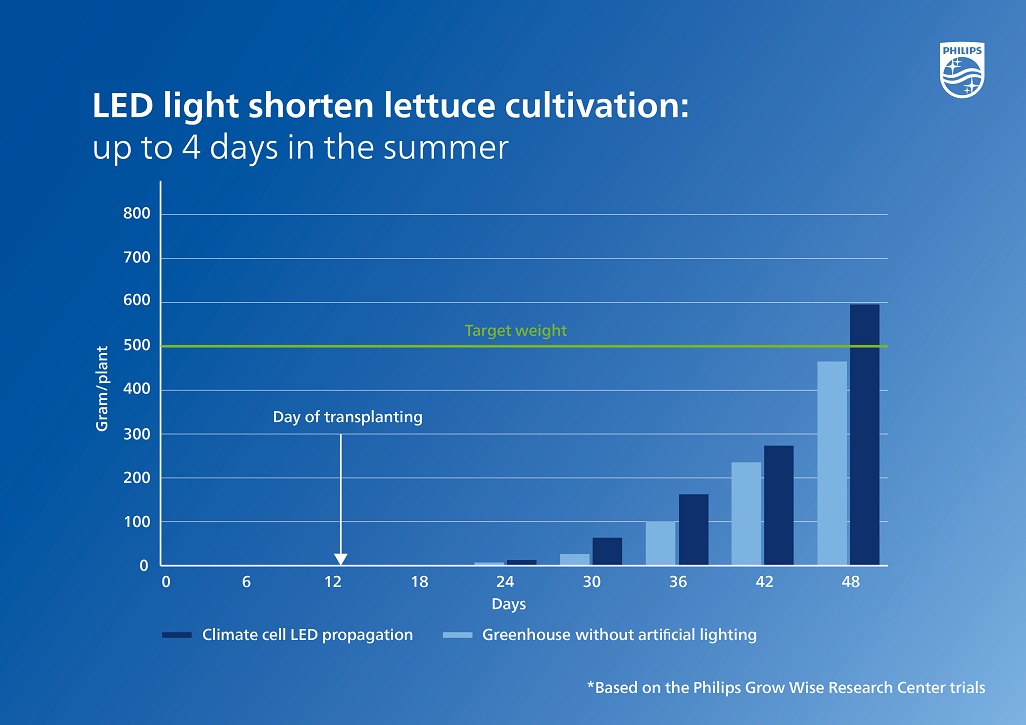

We have been focusing on improving the plant raising phase at our GrowWise Research Center for several years now. In a series of trials, lettuce plants were raised in a controlled environment using LED lighting, and then transplanted to a professional grower’s field. The findings: they grow faster and more uniformly, and a larger number of them grow on well in the field. These trials are demonstrating that the plant is less affected by transplanting and takes root sooner, achieving faster exponential growth (see Figure 1) and resulting in a significantly shorter cultivation time. This could result in more crop cycles per year on the same surface area, ultimately leading to higher production per square meter.

Figure 1: Growth curve of two different raising methods. “Traditional raising” refers to plants raised traditionally in a greenhouse without artificial lighting. “Indoor Farm propagation” is the curve for the young plants raised in a climate cell without daylight, as a function of the time in the field after transplanting.

Effect of far-red light on raising cucumbers and tomatoes

It is well known that the light spectrum can have a major effect on the morphology of plants. However, the specific effects of different colors of light on the growth and development of young plants, and the subsequent impact on the crop after transplanting it into a greenhouse or field, are still largely unknown. In our research program on the raising of heated vegetable plants, we are looking at various facets of these crops. For example, experiments have been carried out to improve uniformity in seedlings, success rates when grafting in climate chambers, and the shoot development after pinching tomatoes.

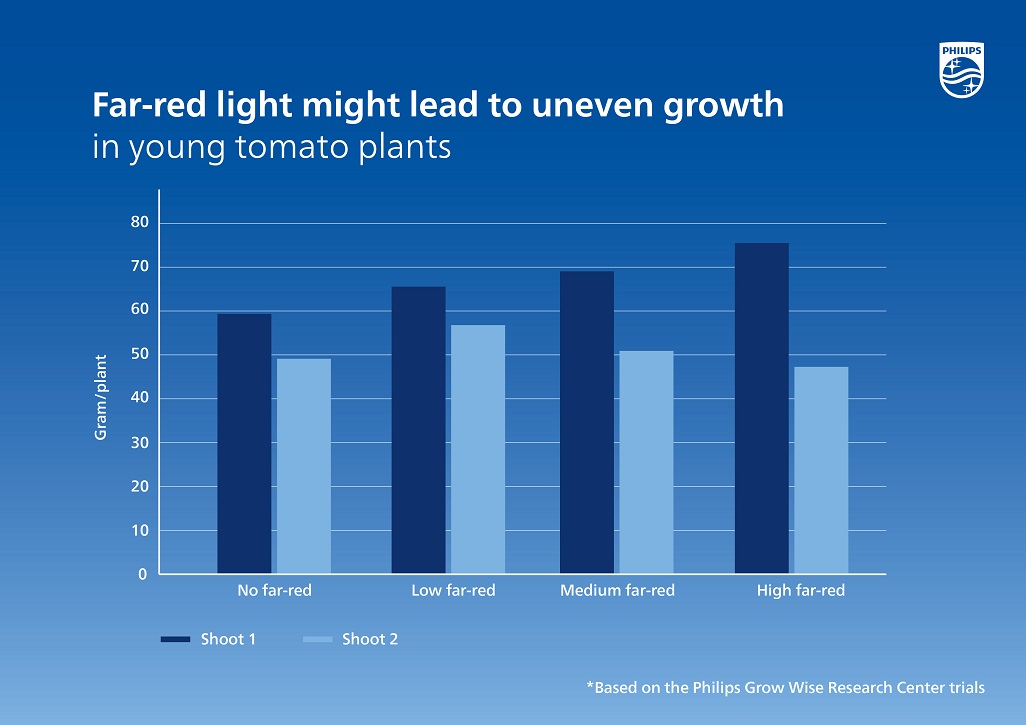

In recent research, we have shown that the use of far-red light during the raising phase of cucumbers can promote the elongation of the crop, creating an open plant structure. In tomatoes, however, it can lead to uneven shoot development. The increasing levels of far-red light in the treatments cause an increasing non-uniformity in the development of the shoots in the young plants (see Figure 2). This suggests that far-red light is not necessary in raising tomatoes and can even have negative effects, to some extent. This can be attributed to the physiological impact of far-red light on the hormone balance in plants, which can stimulate apical dominance and give prominence to the growth of the shoot. The combination of this knowledge and advances in our dynamic lighting techniques gives growers more control over the crop and the ability to provide the right light spectrum at the right time.

Figure 2: Difference between shoots 1 and 2 in a tomato plant with two heads under different light treatments with increasing amounts of far-red light. The weight of shoot 1 remains almost the same with the different treatments. Shoot 2 increases in weight with increasing fractions of far-red light.

Three options for more control over the raising phase

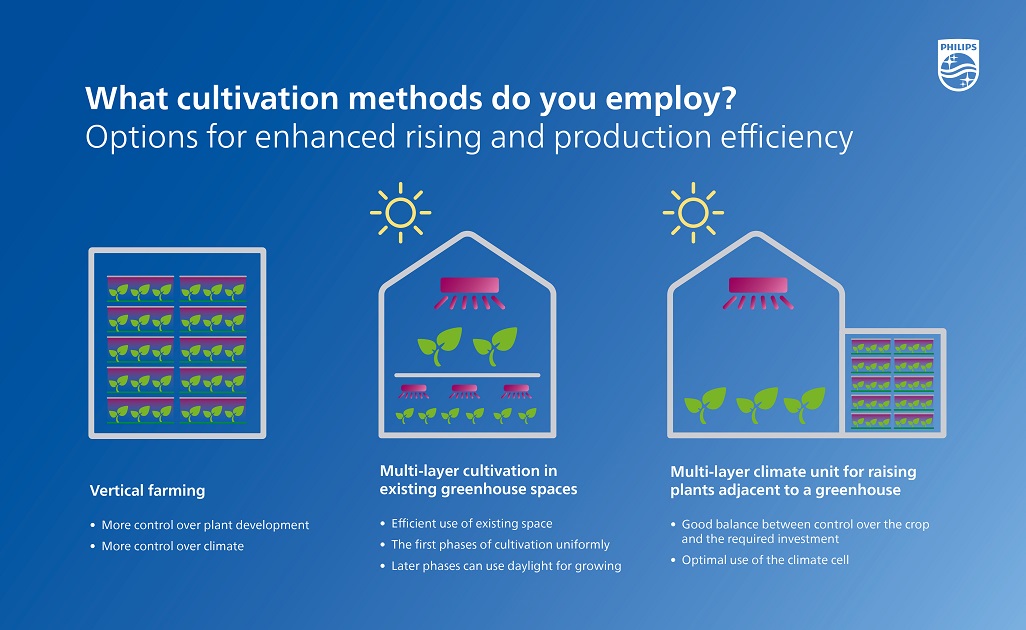

Raising young plants to increase production in greenhouses offers countless possibilities. Many growers are initially deterred from using multi-layer cultivation systems because of the futuristic look, and they often think immediately that it will mean major investments that seem to be too much to handle. Nevertheless, there are several ways to integrate this new development into current techniques and cultivation situations. The unique circumstances of each situation offer opportunities in various areas.

- For example, a “greenhouse without glass” could be a viable option in cases where enough land is available. In this type of greenhouse, the same techniques can be used as in a traditional greenhouse, isolated and with more control over climate, and therefore over plant development.

- If expansion to a larger area is not possible, multi-layer cultivation can be very profitable. This method doubles the cultivation area for each additional layer installed, allowing for more efficient use of existing greenhouse space. In addition, the first phases of cultivation can be used uniformly for germination, rooting or raising, while later phases can use daylight for growing on or hardening off. There are already some examples of this application available, in which multi-layer cultivation is being used successfully in a greenhouse construction.

- A third option is to build a multi-layer climate unit for raising young plants next to an existing greenhouse. The plants can be transferred directly to the greenhouse after the raising stage. Certain crops, such as lettuce or herbs, are particularly suitable for these setups. This makes optimal use of the climate cell, in which the plants are raised at a high plant density and then, when transplanted, they are moved to a greenhouse with lower plant densities. This allows you to create good balance between control over the crop and the required investment. This situation already has some success stories, and the “future” may be closer than we think.

Further developments

We will have several trials taking place in our GrowWise Research Center next season in order to keep raising crops without natural light. Young plants raised without daylight will be transplanted into the greenhouse, so we can monitor the growth process of the plants. Growth rate, harvest weights, dry matter production, flower development, fruit setting and many other aspects will be monitored, depending on the type of crop. In all these trials, the current standard will of course be taken into account, but some more extreme treatments will also be applied in order to test the full potential of modern techniques.

Stefan van de Voort is Plant Specialist for Philips Horticulture LED Solutions at Signify. His work focuses on developing growth recipes for crops grown without daylight. He is always looking for a good balance between growth, quality and economic feasibility. In his work, he looks at cultivation systems, lighting strategies, crop varieties and climate effects, with an eye toward optimizing the complete cycle of the process.

For further information, please contact:

Philips horticulture LED solutions by Signify

Daniela Damoiseaux – global marcom manager

Tel: +316 40578311

E-mail:Daniela.damoiseaux@signify.com

About Signify

Signify (Euronext: LIGHT) is the world leader in lighting for professionals and consumers and lighting for the Internet of Things. Our Philips products, Interact connected lighting systems and data-enabled services, deliver business value and transform life in homes, buildings and public spaces. In 2021, we had sales of EUR 6.9 billion, approximately 37,000 employees and a presence in over 70 countries. We unlock the extraordinary potential of light for brighter lives and a better world. We achieved carbon neutrality in 2020, have been in the Dow Jones Sustainability World Index since our IPO for six consecutive years and were named Industry Leader in 2017, 2018 and 2019. News from Signify is located at the Newsroom, Twitter, LinkedIn and Instagram. Information for investors can be found on the Investor Relations page.

New Zealand Contact:

Graeme Neale

Business Development Manager

Specification, Systems and LED Agriculture Solutions

Mobile + 64 21 2254526

Email graeme.neale@signify.com

Level 3, 123 Carlton Gore Road,

Newmarket, Auckland 1023

Australian Contact:

Aart Slobbe

Account Manager Horticulture LED Solutions

+ 61 448 881 338

Email aart.slobbe@signify.com

Suite 022, 44 Lakeview Drive

Scoresby, VIC 3179, Australia

About Signify

Signify (Euronext: LIGHT) is the world leader in lighting for professionals and consumers and lighting for the Internet of Things. Our Philips products, Interact connected lighting systems and data-enabled services, deliver business value and transform life in homes, buildings and public spaces. With 2020 sales of EUR 6.5 billion, we have approximately 38,000 employees and are present in over 70 countries. We unlock the extraordinary potential of light with smart lighting solutions that improve quality of life, and by working towards a sustainable future. We became a carbon-neutral company in 2020, since our stock market listing, we have been in the Dow Jones Sustainability World Index for four years in a row and were named Industry Leader in 2017, 2018 and 2019. News from Signify is located at the Newsroom, Twitter, LinkedIn and Instagram. Information for investors can be found on the Investor Relations page.

For all media releases please send to marie@grower2grower.co.nz or upload directly: https://www.grower2grower.co.nz/article-form/

CLASSIFIED

Photo

Gallery

Subscribe to our E-Zine

More

From This Category

Integration of Philips GrowWise control system with climate computer allows Huisman Chrysanten to light more effectively and efficiently

New Philips GreenPower LED toplighting force 2.0

Philips GrowWise Research Center to test and showcase intelligent lighting

Can you grow cut chrysanthemums using only red light?

Signify foresees a bright future for vertical farming, driven by automation and diversification.