Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Jan 2020

Automation 2020

Labour costs and available workers- the hottest summer debate

One way for greenhouse growing businesses to remain profitable, with acceptable margins, is to slash energy and greenhouse consumable costs (which is becoming increasingly more unlikely as these keep going up), the other is to reduce labour costs whilst maintaining production. Hence the hot topic at the NZ Horticulture conference last year was automation.

The positive outcome of increasing the minimum wage is that it is forcing all serious greenhouse operations to continually look at how tasks are done, looking at where automating different types of plant work procedures and the product handling systems can make a difference. The advantage of the greenhouse industry is the standard layout of most growing operations which will aid the implantation of mechanical tools.

Politicians, in all their wisdom, have forced our industry, and others, to look seriously and make changes. In the long term these changes may well be positive. However, right now it is apparent that there is a shortage of willing and capable crop workers. This has a major impact on a growers’ willingness to expand their business genuinely concerned about future staff availability. The knock-on effect, from these decisions, impacts many businesses not just a grower’s prosperity!

This year I would like businesses/suppliers to use the Grower2Grower e-magazine to showcase innovative ideas and products that may give growers an opportunity to improve their efficiencies, maintain high quality of production at a reduced labour cost. If you are interested in this opportunity then please contact stefan@grower2grower.co.nz for more information.

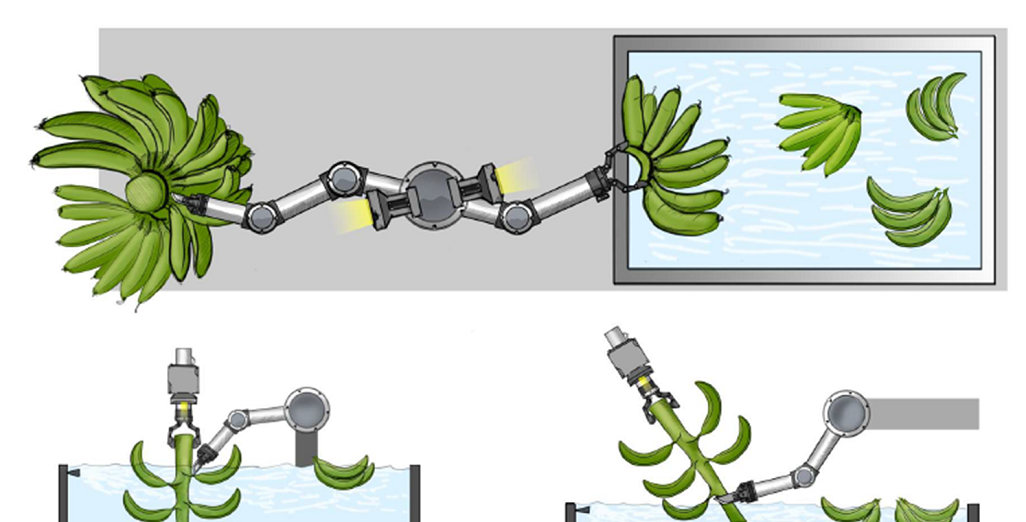

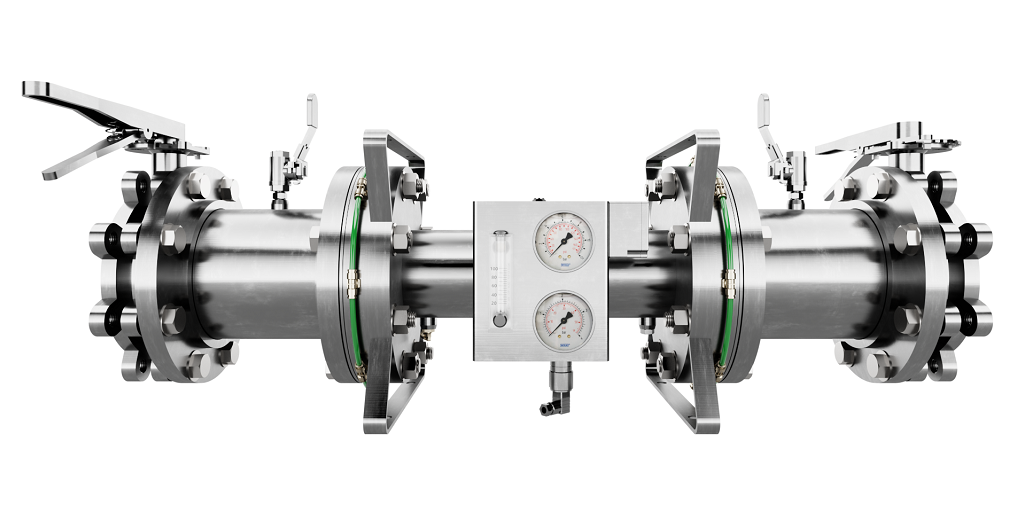

As an example, the Tomsystem, has achieved a large decrease in labour hours for tomato and cucumber growers. This is one of the innovative tools helping growers but I want to know of new products and services or even techniques used that may improve any task for nurseries, flower and vegetable growers.

I appreciate your comments. Please feel free to comment on the grower2grower Facebook page:

https://www.facebook.com/StefanGrower2grower/

Article Written and compiled by Stefan Vogrincic, Consultant, Grower2Grower

Article Edited by Marie Vogrincic, Editor, Grower2Grower

CLASSIFIED

Subscribe to our E-Zine

More

From This Category

John van Santen joins the management of Metazet

Metazet Completes Greenhouse Installation in 2 Days for New R&D Greenhouse

Bale Breaker, Just Press Play

Introducing Moleaer’s Trinity: Revolutionizing Agriculture with Advanced Nanobubble Technology

Punchbowl Packaging – Bagasse trays have replaced their conventional black PET counterparts.