Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Sep 2022

Complacency

PepMV is still as serios today as it was a year ago. The risk of spreading the virus is still a major concern.

Over the last two months it is evident, instore, that PemMV has not vanished as we would have hoped. It is very easy to become complacent around restrictions required to prevent tomato growers becoming infected with PepMV.

I feel like I often deliver bad news – but it is so important that we all continue to be extremely careful and take precautions to prevent PepMV infecting more greenhouses. I have no idea if or when a vaccine will be permitted or available for growers in this country. The strain of PepMV we have is somewhat unique this adds another dimension/challenge for our industry.

What I can be quite confident writing, is that this virus expresses itself in low light conditions and is much less invasive during the rest of the year. The worst two months being July and August. Growers that do have an opportunity to have a three week break between crops or ‘no green bridge’, are in a much better position to eliminate PepMV from their sites if they become infected.

Below is still as important today as it was last year

Prevention:

In my opinion the most important objective for growers is to be vigilant and to increase hygiene measures to reduce the risk of introducing the virus.

While on the Isle of Wight, for Wight Salads in 2007, I worked in an area of the property that had ten individual greenhouses. Two of these greenhouses had PepMV. By using STRICT hygiene protocols, it was contained to those two greenhouses for the period of time I worked there.

One major way to reduce possible spread of PepMV, that is part of the advice below, but I would like to stress is not to share crates, pallets, boxes etc. with other operations. If possible, I would encourage you to use a separate set of crates for picking that only stay on your property and then use another set of crates to pack into for the market. I understand it will be difficult to not mix these crates up. Crates and pallets supplied to your operation, that are in circulation, may accidentally have organic material containing the PepMV. This is a huge concern as pallets, unlike crates, are not washed so this poses an extremely high risk of spreading the virus.

Below are exactly the types of protocols that were used at Wight Salads;

Steps to take at first detection of disease:

- Block off and mark row(s) in which the infected plant or plants were found.

- Enter row, properly suited with coveralls, boots, and gloves, taking care not to touch any plants while walking along the row.

- Remove plant(s) showing symptoms, taking care not to allow contact of the infected plant with adjacent plants, and place in sturdy garbage bag(s).

- Additionally, remove about 3-6 plants (minimum of 20 plants recommended in Europe) on either side of the plant(s) exhibiting symptoms, and place carefully in garbage bags. (note if too many plants in the house are infected then it becomes a ‘wait and see’ to the severity of the strain and damage it causes)

- Walk out of row, taking care not to touch other plants.

- Keep plants in garbage bags and ensure that the plant material does not puncture the bags or containers.

- Burn or deeply bury the infected material, or take immediately to the landfill site. Never dump infected plant material in the open field or leave to be incorporated into the soil in fields. (That is close to your greenhouse where it could be transferred by birds or bees back into your greenhouse the following season or into other greenhouses located nearby)

- Ideally, replace growing media and string in areas from which infected plants were removed, and replace or disinfect drip stakes.

Visitors:

- Have foot-baths filled with fresh disinfectant at every entrance into the operation for disinfection of footwear.

- Disinfect hands using disinfectant dispensers strategically located at all entrances.

- Put on coveralls, disposable boots and gloves.

- Stay in walkways and do not enter the crop.

- When leaving, dispose of boots and gloves into bin specially provided for this purpose.

- Ensure that the used coveralls are laundered before the next use.

- Prevent pets from wandering into the cropping area.

- If this virus is detected in the crop, alert all visitors to its presence and its ease of transmission to avoid inadvertent spread of the disease.

Workers:

- Assign workers, coveralls, tools, carts etc. to greenhouse sections to minimize transfer of the virus between sections. In the case of disease detection, assignment of coveralls, carts etc. to diseased areas is particularly important. At the very least, have shoes/boots and coveralls for each greenhouse area that has been partitioned from the rest of the greenhouse, as might occur in large operations.

- Always work in infected areas last and then leave the greenhouse. Alternatively, shower and change entire work gear before entering uninfected areas again during the same day.

- Dip tools and gloved hands in undiluted skim milk or virucidal disinfectant (Virkon) between every plant. The skim milk should contain at least 3.5% protein, and as soon as the milk starts to go sour, or curdles, replace with fresh milk.

- If knives are used, use a different knife for each row and still disinfect (Virkon) or dip in skim milk between plants.

- After leaving each greenhouse, properly discard disposable gloves and boots, leave shoes/boots for disinfecting, and leave coveralls for laundering and disinfecting.

- Ensure all workers are made aware of the symptoms and that they are instructed to alert the management at first sign of disease symptoms.

- Discourage workers from consuming tomatoes on the premises to avoid inadvertent handling or careless disposal of diseased fruit.

Crates, Carts & Packing:

- Install disinfecting mats at entrances for wheels of carts and forklifts.

- Restrict carts and crates used in infected areas to those areas.

- Do not move carts and crates from infected to non-infected areas.

- Do not share carts, crates, boxes etc. with other operations.

- Tomatoes from external sources for re-packing should not be handled at a site that also produces tomatoes. Such a practice could greatly increase chances of virus transmission to the crop in production.

- Dispose of all rejected tomatoes in a manner similar to that described for plant debris i.e. buried or taken to the landfill immediately.

- Workers in the packing area should preferably not work in production areas also. Where this is unavoidable, workers should always disinfect hands and wear gloves, put on clean coveralls, and disinfect shoes before moving to the production area.

Cultural Practices:

- Do not allow plant debris from de-leafing and de-suckering jobs to be dropped or left on the floor. Remove all plant debris to be burnt, buried, or taken to the landfill.

- Ensure that irrigation water and re-circulated water is disinfected.

- Do not leave trash piles in, or near the greenhouse. Infected plant material can be blown back into the greenhouse, or could be carried on feet and tires.

- Do not keep ornamentals, hobby plants, etc. in the greenhouse. These may serve as hosts for the virus.

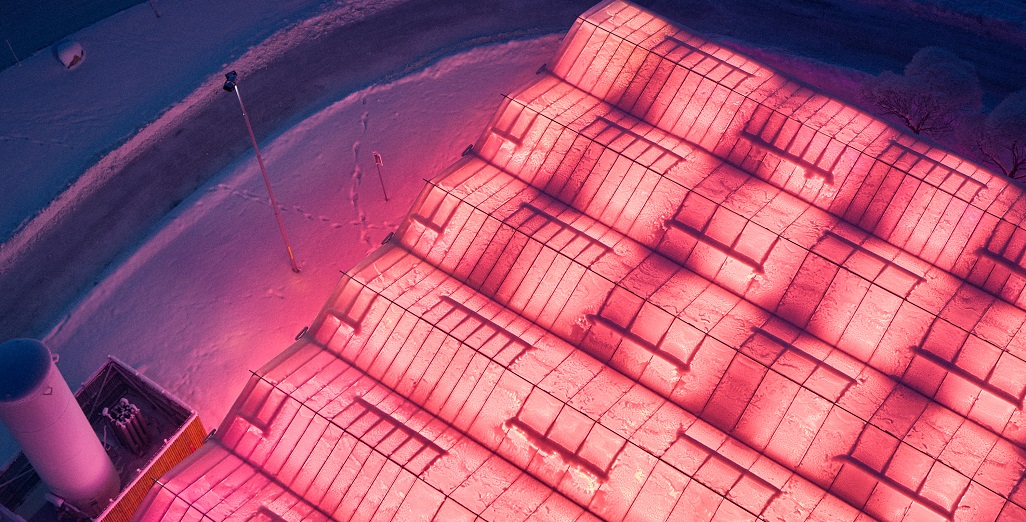

Image from two weeks ago.

Article written and compiled by Stefan Vogrincic

All Article’s checked and edited by Marie Vogrincic

I appreciate your comments. Please feel free to comment on the grower2grower Facebook page:

https://www.facebook.com/StefanGrower2grower/

CLASSIFIED

Photo

Gallery

Subscribe to our E-Zine

More

From This Category

High-tech spy gear to uncover the secrets of Bumble bees in Tasmania

Cherry Production in New Zealand – Mike Nichols

Signify helps Agtira to bring locally grown cucumber to Swedish market

Dimmable Philips LED top-lighting fixtures support maximum efficiency and better use of energy

Plant & Food Research welcomes changes to gene technology regulations