Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Aug 2023

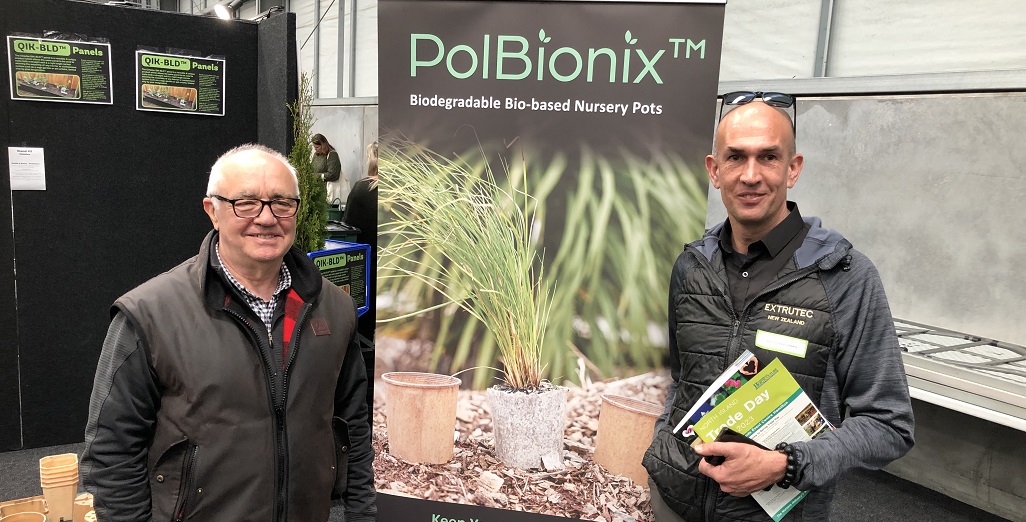

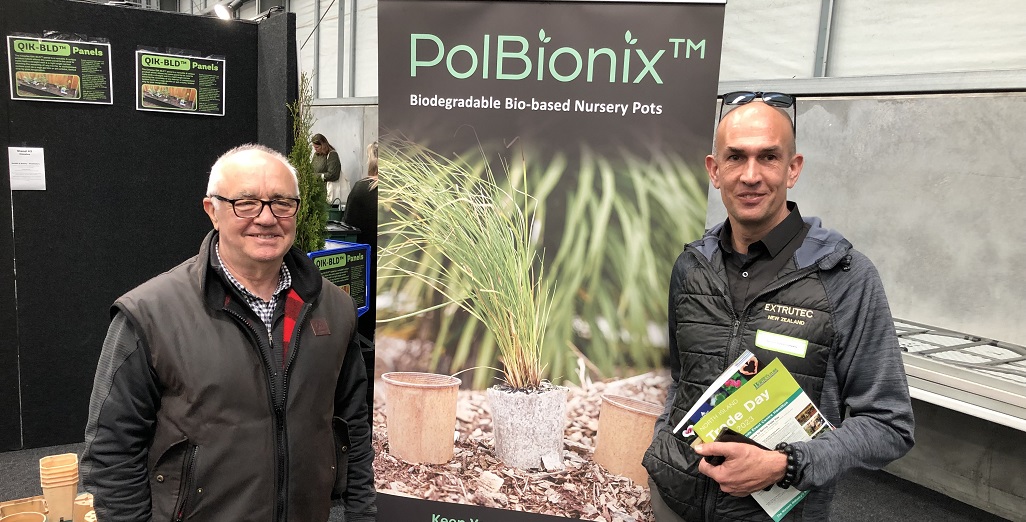

Extrutec’s Joe Wiid explains the connection with Polbionix and providing raw material for compostable pots.

Recently at the Nursery Trade Day in Hamilton I was able to meet up with industry leaders. One of those was Joe Wiid Managing Director of Extrutec and Peter Wilson, Founder and Director of William and Ross that have developed a biodegradable bio-based plastic – Polbionix.

PolBionix™ a biodegradable bio-based plastic that biodegrades in mild environments leaving only water, carbon dioxide and microbial biomass. PolBionix™ biodegrades in home composts inside 12 months and soils and gardens inside 24 months.

Joe Wiid explains the connection with Polbionix and providing raw material:

“When we started making biodegradable and compostable products for growers, we found out very early in that journey that not only is the range of biomaterials very limited, but the available bio-polymers all have limitations. This meant that we often could not use off-the-shelf raw materials to make biodegradable products to the specifications that growers require. Initially it was necessity and later curiosity that led us on a path of developing our own raw materials. We used our knowledge of conventional and bioplastics and started experimenting with compounding the available raw materials with organic additives and fillers.

Little did we know then that all those trials and testing of new recipes would open up a completely new business opportunity for Extrutec. As more and more biodegradable products are now being developed, these innovators are running into the same challenges we did a few years ago. However, with the experience and knowledge base we have developed during our own trials, we are now able to offer them assistance not only in providing advice and consulting but we are also able to make or compound novel raw materials for them. Having tested literally hundreds of combinations and formulations, we have a good idea of the specifications that can be achieved and what is likely to work in any particular environment. Obviously, every new product should still go through a rigorous field trial to test that it performs as required, but the product development journey can be substantially shortened if you have an idea of what might work, at the onset. Our focus is very much on developing new raw materials that are biodegradable or compostable not only for the sake of being “green”, but it also has to meet technical specifications and functional requirements. We strongly believe that this is what distinguishes a “good idea” from a “good idea that can be successfully commercialised”.

One of the novel raw materials we have recently worked on is a compound containing an organic filler. The formulation had already been developed by the time we got involved, but the owner of the idea (Peter) had difficulty finding someone to make the raw material for him. As a New Zealand based manufacturer, we could address several challenges like getting a small amount of raw material compounded while the product is still in a trial phase, having the flexibility to tweak the formulation if the field trials identified issues or opportunities for making it even better and getting the material made in a relatively short timeframe and at a very reasonable cost”.

Above image – a range of Polbionix biodegradable pots.

Below image – Left Peter Wilson and Right Joe Wiid.

Contact details

Phone: +64 9 988 9560

Email: info@extrutec.co.nz

Address: PO Box 281, Ruakaka 0151 NZ

Web: https://extrutec.co.nz/

CLASSIFIED

Photo

Gallery

Subscribe to our E-Zine

More

From This Category

Calling on suppliers to do the right thing (Hygiene)

Botrytis Alert: Key Strategies to Minimize Losses

Blight Hits South Auckland – One Grower Severely Affected

Roam presentation on hygiene protocols for greenhouses and biosecurity, Pukekohe, New Zealand

PUKEKOHE WORKSHOP 26th February: Strengthening Biosecurity to Prevent ToBRFV in New Zealand