Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Aug 2018

Gourmet Mokai – LED installation inspiring

Piet Hein van Baar from Philips presentation was informative and educational

Mid last year Gourmet Mokai decided to install LED’s on a large trial basis to increase their winter production of Campari. Gourmet Mokai is the first company, in NZ, to install LED supplementary lighting for a commercially grown crop of tomatoes. The selected site was a 4000m2 glasshouse situated at Mokai, which is growing the popular Campari truss tomatoes. In other parts of the world supplementary lighting in greenhouses is not new, I remember back in 2007 LED’s were used by the company I was working for in England. Since then the knowledge and technical advancements have improved immensely.

Philips Lighting, now known as Signify, in conjunction with Gourmet Mokai hosted an open day on Wednesday the 8th of August at Mokai, near Taupo, New Zealand. The day encompassed three presentations, a crop walk and discussion. Over 60 growers and suppliers attended. What impressed me the most was the technical growing knowledge Philips has gathered and how comprehensive their research is.

Piet Hein van Baar, lighting specialist from Philips, presented a very compelling story backed up by real figures, as Piet said this is “no fake news”. Presenting the percentage increase, one might achieve in their own production facility was a focus. By using a grower’s crop and environmental data, Philips have come up with formulas which will help grower’s understand what they could potentially achieve growing with LED’s. Philips are not just trying to sell you LED’s, they have employed plant specialists to help growers, which will be crucial in optimising the benefits of LED’s. Regardless what variety you are growing their guidance and advice will be tailored to your requirements.

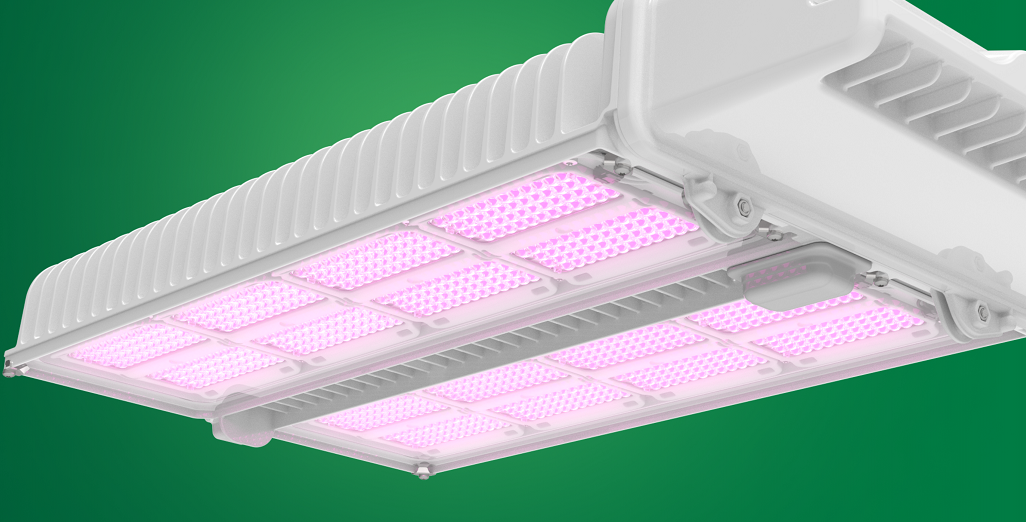

Part of the presentation was dedicated to the ‘spectrum of light’ and in this case the effects on plants, a comparison was then made between the capabilities LED’s have compared to High Pressure Sodium (HPS) lights and what they offer to the plant. The level of blue and red light that LED’s supply, which is important for plant growth, is far superior to that of HPS. Grower’s in Belgium that were using HPS, are now either integrating HPS with LED’s or switching completely to LED’s. Philips have come up with formulas to calculate different lighting options, how much power/m2 consumption there is and how much PAR light is achieved using combinations of HPS and LED’s and LED’s alone. It is certainly evident from the figures that if you solely use LED’s you will use a lot less power and have sufficient PAR light for effective growth.

- The numbers:

1, How many micro-mol of LED lighting would you need?

What you aim to achieve will determine how much light intensity is recommended. Gourmet Mokai have installed a top light and an inter-light. The installed light intensity for the top light is 125 µmol/m²/s. For the inter-light, the installed light inensity is 75 µmol/m²/s. The inter-light plays an important role in increasing the photosynthesis of leaves which otherwise are inefficient.

2, How much extra production will it give me?

Once you have figured out how much extra production supplementary lighting will potentially harvest, you then need to work out when it will give you that extra production. If for example LED’s will give you an increase of 50% production on an annual basis, when are you achieving most of those gains? The answer is during low light periods. You should have the ability to produce consistent summer production during the winter, at winter pricing, from that you will be able to estimate the financial return from produce sold. There will be a point during a year that unless you have very poor weather that the benefits of using LED’s are probably not going to give you better returns. Having the option to use supplementary lighting in spring and summer still appeals to me.

3, What is the extra running cost?

Power: To gain an accurate usage you would have to calculate the wattage usage the lights designed for you use, take those figures with suggested hours the lights would work and calculate power usage. The suggestion from the trial is that it would double your power consumption during the periods you are using the LED’s. Currently no growers in NZ to my knowledge use combined heat and power generators (CHP) so when you sit down with your lighting specialist you will need to figure out exactly how much extra power you will need and if your electricity supplier will be able to supply you.

Other considerations:

- Labour: You will have increased labour, work on what you would use in the Summer.

- Fertiliser: There will be have an increase in winter fertiliser cost. Estimate using summer consumption.

- Heating: More heat input will be required to maximise the benefits. Achieving the temperature in the middle of winter is a major consideration. Growers who have screens will find it easier to maintain the extra temperature needed to grow a balanced crop.

- Screens:If you don’t have screens and were to either retrofit or if you are building from new then I would install black out screens which doubled up as thermal screens. Light pollution regulations in built up areas would certainly only be a complaint away. Kill two birds with one stone.

- CO2: A very good question was posed as to how effective the lights were if growers did not have supplementary CO2. A number of growers do not grow with supplementary CO2 in NZ. It was recommended that you should use CO2 and use a level of 600ppm as an average while the lights were on. Even though many growers are without CO2 it would not be practical to vent at night when the lights are on to have ambient CO2 brought into your greenhouse, and if you did manage to keep a constant ambient CO2 level of around 400ppm you still would not capitalise on the extra benefits. Therefore, the conclusion was if you cannot access CO2 this would probably not be a viable option.

- How long are LED’s lifespan: The LED lifespan is estimated at 35000 hours. If you used your lights for six months of the year and had them on for 18 hours per day then you would use approximately 3200 hours per year, that would put the time to replace the lights at approximately eleven year interval. They have calculated if you did not replace your LED’s until they reached 45000 hours that the last 10000 hours would still potentially give you 90% effectiveness.

- Capital Cost and time for return on investment: There is a huge range of options available to growers, which suit the differing needs growers have, so the cost of installing the lights will vary, the estimation that was given was between $180-300 per m2. The potential return on investment will be determined in part by the market prices and the skill of the grower to maximise yields but the time to get a return on your investment could be between 3-6 years. HPS lighting would be cheaper to install but the energy consumption would be higher. HPS produces excess heat and reducing the effect this has on the head of the plant and how to ‘get rid’ of the excess heat is another consideration. Greenhouse height and how far from the top of your head the lights are is important (especially HPS). Ideally the higher your greenhouse, the better, however the Philips plant specialists will go through the options with you to find a solution.Initially most (but not all) growers will be hesitant to investigate installing LED’s because of the capital outlay. This is certain, but with an increase in scale and ever improving technology, pricing in the future could become “more affordable”.

- Grow Pipes: Grow pipes are a great tool if you have inter-lighting as they keep the belly of the plant warm and this helps the transpiration. I would highly recommend you have a grow pipe if you are considering top and inter-lighting.

- Marketing: A major benefit is the certainty of production and being able to supply your market, especially during the winter period. If it is a game changer for the grower it is also a game changer for the retailer which will give certainty of supply.

I would like to thank Piet Hein van Baar and Aart Slobbe for their presentations which were based on fact, science and real figures that growers are achieving. It was a fascinating insight into the present and the future.

It is extremely important growers have accurate costings and projected returns. Philips have the resources which has made it much easier for growers to work through. I would highly recommend investigating the potential of using LED’s if you can meet the criteria to achieve their full potential.

Photo Gallery:

Over 60 industry recognised people attended the open day and were treated to a look into the future.

Pukekohe cherry tomato grower Peter Faucitt was just one of many greenhouse growers that attended the open day.

Piet with Steve Dickson from Premier Seeds.

Photo clearly illustrating both the top light and inter light.

This article is an initial insight into LED’s. There are many more technical questions that the lighting and plant experts from Philips (Signify) will be able to help you with.

I appreciate your comments. Please feel free to comment below or on the grower2grower Facebook page:

https://www.facebook.com/StefanGrower2grower/

Article Written by Stefan Vogrincic, Consultant, Grower2Grower

CLASSIFIED

Subscribe to our E-Zine

More

From This Category

Integration of Philips GrowWise control system with climate computer allows Huisman Chrysanten to light more effectively and efficiently

New Philips GreenPower LED toplighting force 2.0

Philips GrowWise Research Center to test and showcase intelligent lighting

Can you grow cut chrysanthemums using only red light?

Signify foresees a bright future for vertical farming, driven by automation and diversification.