Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Aug 2023

LLEAF Pty Ltd received the prestigious Physical Sciences Fund

LLEAF, which stands for Luminescent Light Emitting Agricultural Films, has since marketed its unique product.

Sydney, Australia – July 24, 2023 – Last night, LLEAF Pty Ltd, an innovative Sydney-based

agtech startup, celebrated the inauguration of its new solar laboratory facility in Mona Vale.

The event was officiated by The New South Wales Chief Scientist Professor Hugh

Durrant-Whyte, marked by a symbolic planting of the final lettuce in the new hydroponic

system.

LLEAF Pty Ltd received the prestigious Physical Sciences Fund, a competitive development

and commercialisation program for technological innovations from The Office of The NSW

Chief Scientist in December 2021. This substantial financial backing proved to be a

game-changer, setting in motion a series of events that have led to LLEAF’s success today.

The company launched its minimum viable product (MVP) to the market in January 2022

and shortly after, secured its first customers. LLEAF was later published in New Scientist

and went on to raise a $3.5M seed round led by two Danish climate-focused funds and

participated in by the University of New South Wales, and Cicada Innovations.

LLEAF, which stands for Luminescent Light Emitting Agricultural Films, has since marketed

its unique product. It engages with the greenhouse horticulture industry, providing colour

conversion films that boost plant growth by approximately 20%. LLEAF’s technology allows

custom sunlight spectrums, termed “sunlight engineering”, resulting in various beneficial

outcomes such as seasonal shifting for out-of-season or new location fruiting. COO Chris

Wilkins said “the technology allows for greenhouse plastic to behave like an LED light –

emitting additional red light into the greenhouse which is what plants use to produce cellular

energy”.

The opening event was graced by esteemed guests including Dr. Sophie Scamps MP,

Federal Member for Mackellar, Rory Amon MP, State Member for Pittwater, Sue Heins,

Mayor of The Northern Beaches Council, Luke McQuillan from The Future Foods CRC, Rick

Jordan from Sustinent and Dr. Richard Thomas from Western Sydney University. Dr

Thomas’ work with The NSW DPI on ‘The Blueberry Nutritional Optimisation Project’ uses

LLEAF’s films to study the change in flavonoid levels in plants. From the LLEAF team in

attendance was Chief Operating Officer Chris Wilkins, CEO Dr. Alexander Soeriyadi, and

Marketing Manager Ariba Farid.

Since receiving the Physical Sciences Fund, LLEAF expanded its services to include

scientific measurement and inquiry, recognising its potential in this field. The result is the

cutting-edge solar laboratory and a connected devices system. This system, when placed

inside a greenhouse, monitors air quality, including spectrum, oxygen, carbon dioxide,

humidity, temperature, and air pressure, and provides essential data at an affordable cost.

The Solar Laboratory consists of 3 isolated chambers each housing high-tech plasma lamps,

with each lamp creating a floating marble-sized ball of plasma reaching 6000 degrees

Celsius, the artificial suns. “These lamps produce an almost perfect simulation of sunlight

and being controlled by the computer we can program the sunrise and sunset to simulate

real world conditions in the lab” said COO Chris Wilkins. This ability to mimic real-world

conditions, enables LLEAF to accurately forecast the yield a grower can expect when

constructing a new greenhouse or when switching to LLEAF film.

LLEAF is now working with universities to improve the efficiency of PV solar panels using its

colour conversion and spectrum-shifting films, and looking to develop semi-transparent PV

solar for greenhouses. Chris Wilkins, COO of LLEAF, said, “The potential now is huge and

The Physical Sciences Fund was precisely the targeted support LLEAF needed at the time.”

LLEAF continues to make waves in the agtech industry and is recognised as a Tech23

startup for 2023, an event hosted by Cicada Innovations. The company’s trajectory shows no

signs of slowing down.

About LLEAF Pty Ltd

LLEAF Pty Ltd is a pioneering Sydney-based agtech startup that specialises in ‘sunlight

engineering’. Their ground-breaking colour conversion films and comprehensive monitoring

systems are transforming greenhouse horticulture, making efficient and out-of-season

production a reality.

Press Contact:

Chris Wilkins

chris.wilkins@lleaf.com.au

+61 0492815067

CLASSIFIED

Photo

Gallery

Subscribe to our E-Zine

More

From This Category

John van Santen joins the management of Metazet

Metazet Completes Greenhouse Installation in 2 Days for New R&D Greenhouse

Bale Breaker, Just Press Play

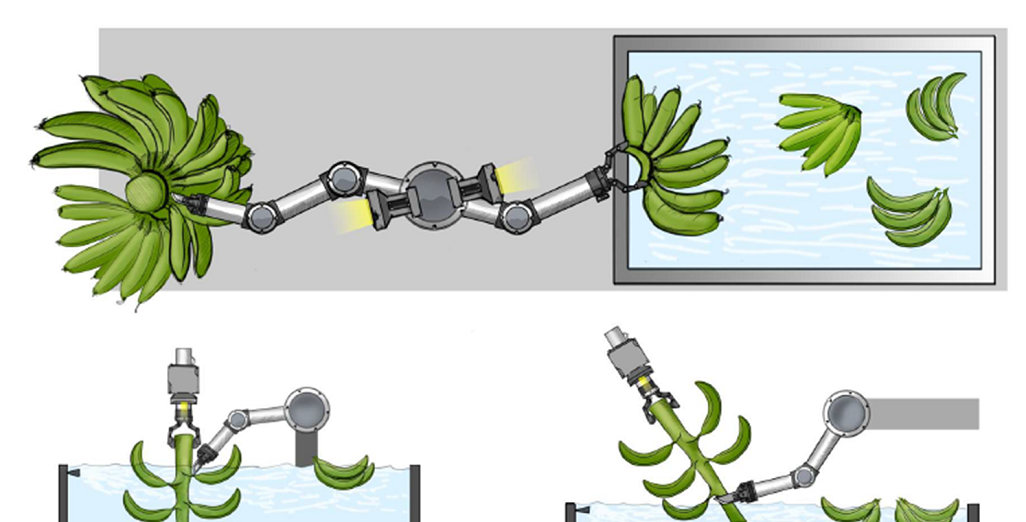

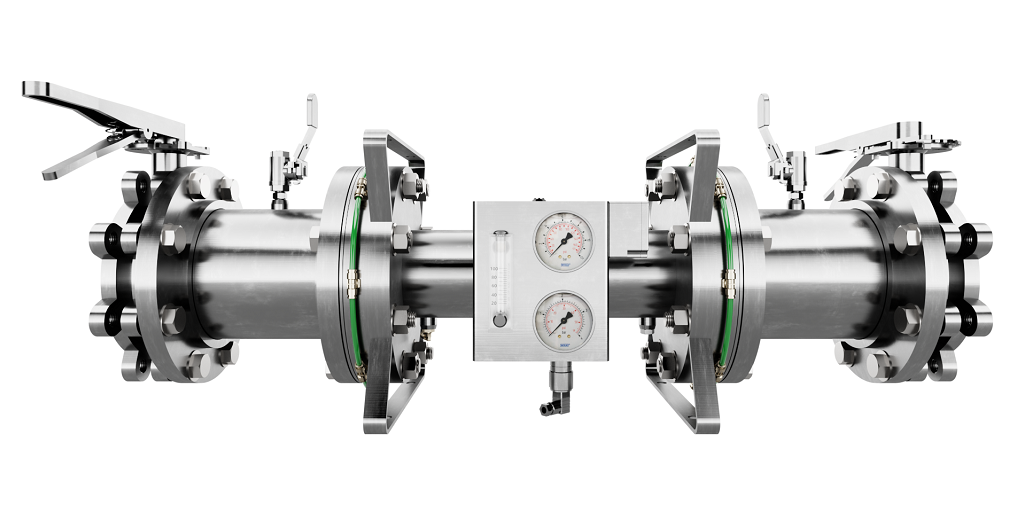

Introducing Moleaer’s Trinity: Revolutionizing Agriculture with Advanced Nanobubble Technology

Punchbowl Packaging – Bagasse trays have replaced their conventional black PET counterparts.