Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Ingenuity at its best

Recently I went along, with several local cucumber and tomato growers, to see the first demonstration of a prototype crop-removal machine developed by Makhan and Ranjit Singh from Bmak Evergreen Ltd. The operation covers 2.5 ha of greenhouse growing telegraph cucumbers and a small number of tomatoes in the North Waikato and South Auckland districts.

It was fascinating to see how a medium sized company has overcome a huge issue with a relatively small investment. Similar types of equipment are available internationally but are expensive and it’s hard to justify the cost of importing to NZ.

Below are some questions I asked Ranjit Singh, Growing Manager of Bmak Evergreen:

Why did you develop the crop-removal machine?

- This machine was developed for the overall health and wellbeing of our staff and economic benefits. Labour can be reduced, and it can also save time. Benefits to the employees’ health was also noted, as it does not require any heavy lifting.

Who developed this prototype?

- This prototype was initially developed by my Father Makhan Singh and me. Later the concept was discussed with local company Ultimate Tech, owned by Masarat and Naweed Khan.

What improvements will you make?

- The speed of the pullout machine will be increased in future.

How much labour/time has this saved you?

- Currently the time is similar however, the labour units required is vastly reduced. Previously we used up to twenty-five staff to do the crop removals. With the new prototype we only require three staff.

How has the crop removal equipment improved the wellbeing of the staff?

- During the crop removals, heavy lifting and repetitive movement was required which can affect the lower back and can cause discomfort to the employees. This would also result in less work efficiency and increased sick leave. Since replacing the physically challenging task of manual crop removals, we have immediately seen better health and safety outcomes for our employees.

Father and Son and owners of Bmak Evergreen Ltd, Makhan Singh left and Ranjit Singh Right

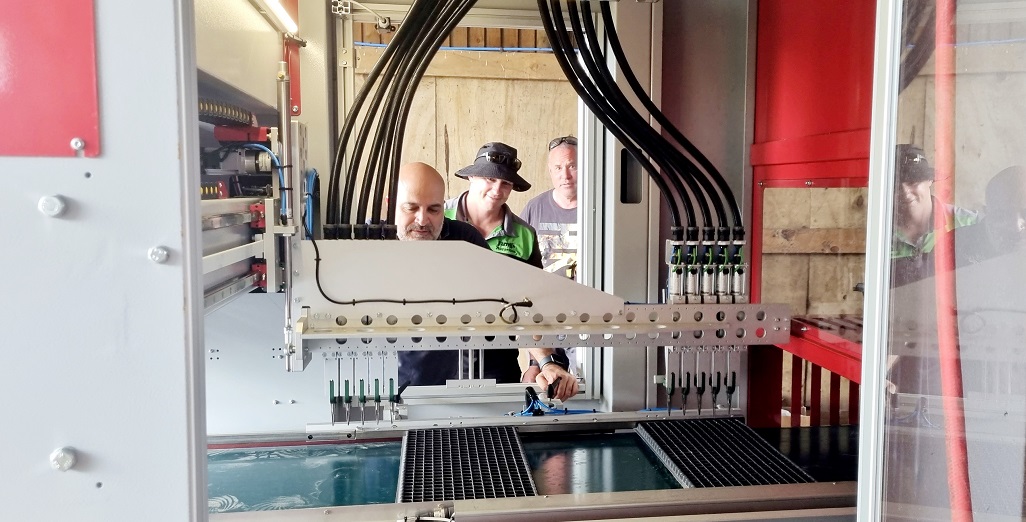

Only three staff required to pull out the plants via the prototype machine using mats.

Local growers were invited to see the second crop removal using the prototype.

Engineer and co-designer of the equipment Masarat Khan from Ultimate Tech Ltd

Article written and compiled by Stefan Vogrincic

All Article’s checked and edited by Marie Vogrincic

I appreciate your comments. Please feel free to comment on the grower2grower Facebook page:

CLASSIFIED

Photo

Gallery

Subscribe to our E-Zine

More

From This Category

Metazet Completes Greenhouse Installation in 2 Days for New R&D Greenhouse

Bale Breaker, Just Press Play

Introducing Moleaer’s Trinity: Revolutionizing Agriculture with Advanced Nanobubble Technology

Punchbowl Packaging – Bagasse trays have replaced their conventional black PET counterparts.

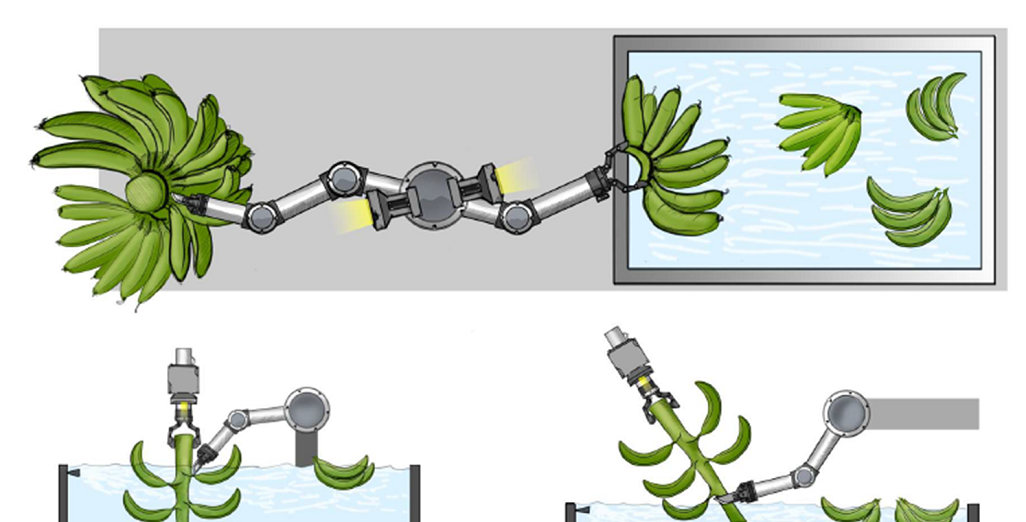

Robots to make banana processing more a-peeling