Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Oct 2023

Maxi Tray Washer contributed with 12% increase in production.

Microgreens – Maximum results!

Longkeeper Farm are growers of microgreens bursting with flavour. Located in the Bombay Hills, south of Auckland, the team are hard at work, bringing superfoods to the supermarket and chefs kitchens.

These living microgreens are grown in a large greenhouse with full climate control systems. Daily planting and harvesting allows the product to be delivered fresh to a demanding marketplace, all year round.

As part of their mission towards sustainable growth and achieving high crop yields in a small space, Longkeeper Farm embrace traditional growing techniques, paired with new technologies. One important step involves reusing the microgreen nursery trays.

But if nursery trays are not carefully washed and sanitised, plant disease, pests, viruses and other nasties can thrive. By cleaning the trays the next seedlings can get off to a clean and healthy start. When done manually, tray washing is a slow process and can lack quality control. Seedlings grown on a commercial scale that have health issues can be destructive to growers as they try to rectify the problem.

Recently, Longkeeper Farm founder & co-owner, Peter Thornley, approached horticulture and nursery automation specialist, PrimeHort, for an automated solution to this tedious task.

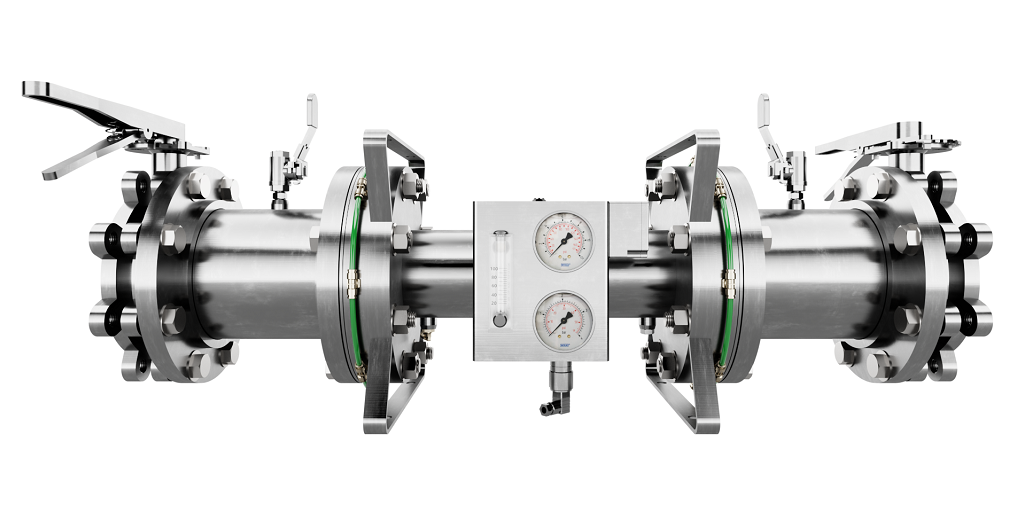

PrimeHort recommended a streamlined, simple ‘one pass’ Maxi Tray Washer and Peter is impressed with the results.

“We are very happy with the tray washer. It does exactly what we want. We can easily wash 400-500 trays an hour. We’ve also noticed a 12% increase in yield of our microgreens, simply by washing our trays. I don’t know why every microgreen grower doesn’t have one.”

Some of the key features that Longkeeper Farm respect about the Maxi Tray Washer is its ability to filter and recycle its dirty water, plus recycle its spray treatment. They also appreciate the adjustable speed, high-pressure, double-rotating cleaning jets, and that it came with an inbuilt multi-stage pump (saving them from buying a pump). For circa $45,000 the machine will repay itself quickly.

Next up, PrimeHort will work with Peter on a suitable tray stacking unit to catch the trays at the completion of their wash cycle.

Within the family of Tray Washer solutions at PrimeHort is the Tray Washer MINI which is a maintenance free, simple to use machine, suitable for virtually all types and sizes of trays. Built in 316 marine grade stainless steel, the tray cleaner has 2 fast rotating spray arms which are driven by a high-pressure pump (not included). In a separate chamber the trays can be sterilised with a treatment spray. The continuous moving conveyor belt has special profile (cleats) and (optional) adjustable speed.

If you’re in search of the pinnacle of tray washers, the DaRos LC1 model is a strong contender. The LC1 boasts an array of features and advantages that elevate its tray cleaning capabilities to an exceptional level.

Among the features is an automatic tray in-feed conveyor, which streamlines the tray loading process, along with high-pressure spinning jets and fixed jets positioned both above and below the tray, ensuring a thorough wash. Optional drying fans can be incorporated after washing to leave trays impeccably dry.

Also, the LC1 Tray Washer offers a spray treatment wash, complete with spray recycling, drying fans after spraying, a tray stacking unit, and end rollers for added convenience and efficiency. The standout feature of the LC1 is the large external water recycling unit. The inclusion of internal drawer filters within the main tray washer removes the bulk of soil and debris, allowing the external water recycling unit to facilitate prolonged washing operations while using minimal water.

If you would like to discuss how Tray Washers could benefit your nursery business, please give the PrimeHort team a call today on 0800 12 77 46 or email sales@primehort.co.nz.

CLASSIFIED

Photo

Gallery

Subscribe to our E-Zine

More

From This Category

John van Santen joins the management of Metazet

Metazet Completes Greenhouse Installation in 2 Days for New R&D Greenhouse

Bale Breaker, Just Press Play

Introducing Moleaer’s Trinity: Revolutionizing Agriculture with Advanced Nanobubble Technology

Punchbowl Packaging – Bagasse trays have replaced their conventional black PET counterparts.