Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Jun 2022

New Zealand grower enthusiastic about on-site peroxide generation

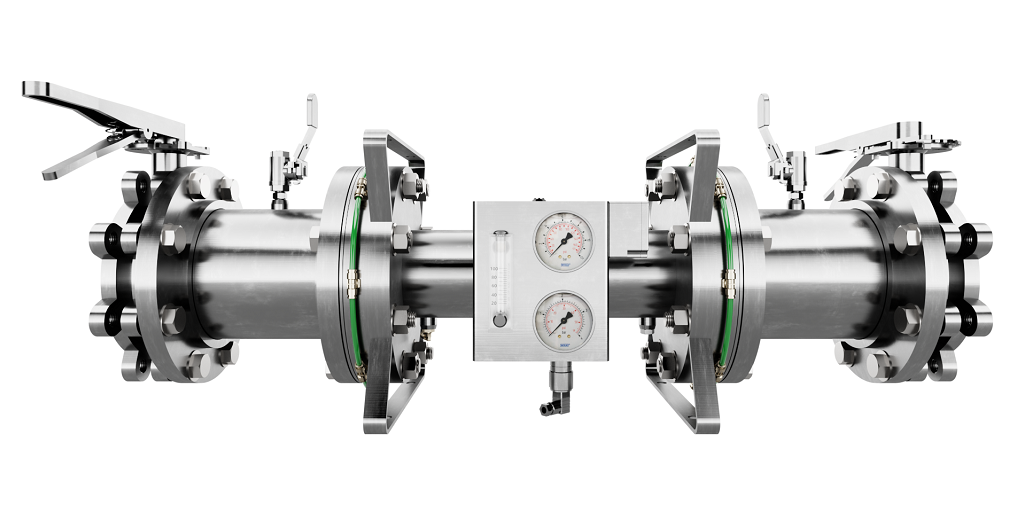

HPGen™ supports safety, simplicity and cleaner irrigation at Jade Garden

Jade Garden is an important supplier of cucumbers to the local market in the South Island of New Zealand. At their glasshouses in Christchurch, the company emphasizes a safe environment for their employees and healthy conditions for their telegraph cucumbers to grow. For these reasons, the HPGen™ has been a natural match for the grower, and farm manager Robert Lindsay is enthusiastic about the results he’s seen so far.

Safety

The HPGen™ allows the grower to generate Peroxide UltraPure™ directly on site, which means they don’t have to buy hazardous bulk peroxide anymore. “Staff are not handling a concentrated hazardous substance, and so this supports our commitment to creating a safer workplace”, Robert comments.

Simplicity

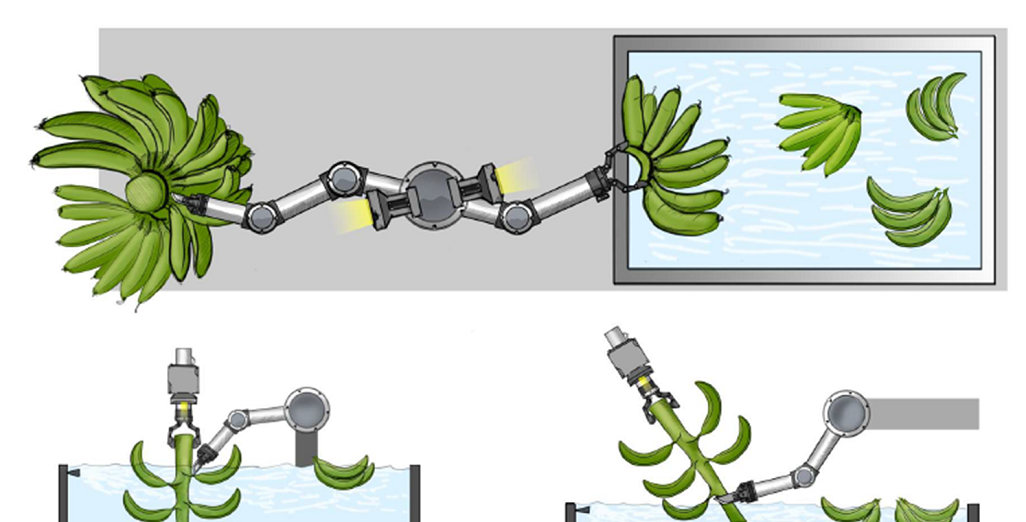

The HPGen™ is both easy to install and to use. It’s connected directly to both the greenhouse run-off water treatment system and the irrigation system, and the HP Now unit is monitored online to make sure everything runs smoothly. “Dosing hydrogen peroxide into the irrigation system happens automatically,” Robert explains, “no extra effort required.”

Cleaner irrigation system

Cleaner irrigation system

Hydrogen peroxide is known to combat biofilm in irrigation lines, so Robert expected the HPGen™ system to contribute to a cleaner irrigation system. “I expected to see less biofilm in the irrigation mains, submains and laterals, but I was surprised at how quickly this occurred. In the first three weeks of operation I noticed the mainline filters blocking more frequently, which indicated that the biofilm in the lines was being oxidized by the peroxide. While altering a mainline recently, I noticed far less biofilm in the section I checked. This will likely continue until we have clean mains, submains and laterals”.

Oxygenation of irrigation water

Another added benefit of the Peroxide UltraPure™ generated by the HPGen™ system, is that it breaks down to pure water and oxygen. The extra oxygen molecule gives crops a boost, something Robert confirms: “I believe that any excess peroxide in the irrigation water will contribute positively to the oxygenation of the root zone.”

Treatment of drain water

Root health is very important when growing hydroponically, Robert notes. “Diseases such as Pythium can have a devastating effect on root health and thus production. All irrigation drain water from our greenhouses is dosed with peroxide and then left to settle before being passed through a UV unit. This double redundancy system means that if one of those two systems ever fails, then we still have coverage from the second. This will allow us time to fix the broken system.”

About HPNow

HPNow addresses growing global challenges in clean water and sanitation through its range of on-site, autonomous, safe and sustainable hydrogen peroxide generation solutions. Headquartered in Copenhagen, and with representation across Europe, the Americas and Asia, they address their clients’ water treatment needs in market segments ranging from agriculture and aquaculture, to industrial and drinking water treatment. HPNow is a technology and market leader in on-site generation of hydrogen peroxide, and is continuously striving to further advance its technology and products in order to meet growing market needs and rising global demand.

Stay in the loop by following HPNow on LinkedIn and Facebook.

Contact the HPNow team directly at sales@hpnow.com

HPNow

Jan Jacob Mekes – Marketing & Communications

Cover Photo Robert Lindsay

CLASSIFIED

Photo

Gallery

Subscribe to our E-Zine

More

From This Category

John van Santen joins the management of Metazet

Metazet Completes Greenhouse Installation in 2 Days for New R&D Greenhouse

Bale Breaker, Just Press Play

Introducing Moleaer’s Trinity: Revolutionizing Agriculture with Advanced Nanobubble Technology

Punchbowl Packaging – Bagasse trays have replaced their conventional black PET counterparts.