Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

Aug 2018

Robots Picking Capsicums

The future is coming whether you want it or not

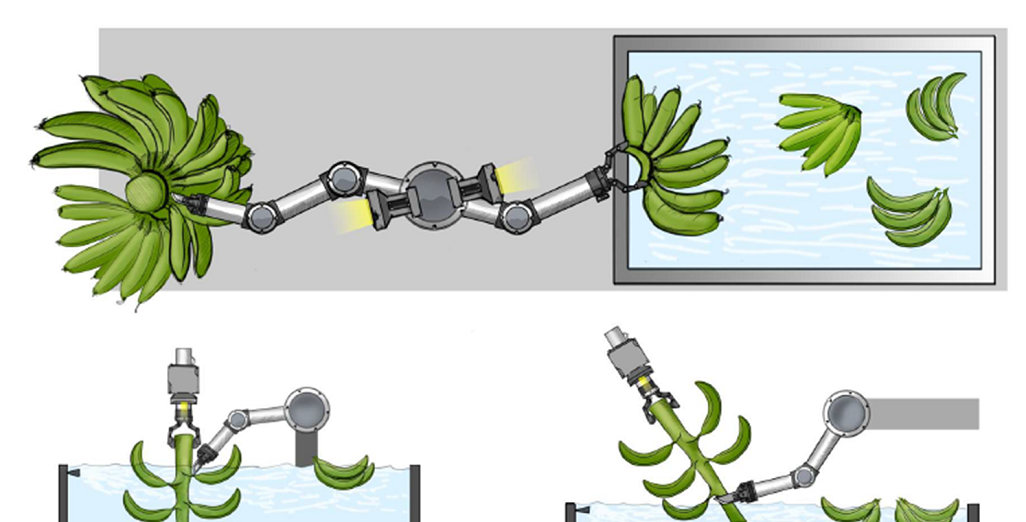

“The SWEEPER robot is the first sweet pepper harvesting robot in the world demonstrated in a commercial greenhouse. It is designed to operate in a single stem row cropping system, with a crop having non-clustered fruits and little leaf occlusion. Tests were performed in a commercial greenhouse having a 2-row V-type cropping system. Preliminary test results showed that by using a commercially available crop modified to mimic the required conditions, the robot harvests ripe fruits in 24 seconds with a success rate of 62%. Based upon these results, the Sweeper consortium expects that a commercial sweet pepper harvesting robot will be available within 4-5 years. Further research is needed to make the robot work even faster and reach a higher harvest success rate. Next, a commercially viable single-stem row cropping must be developed and the breeding companies must develop crop cultivars that are more suitable for robotic harvesting. The obtained results can also be used for robotic harvesting of other crops. (Reference http://www.sweeper-robot.eu/11-news/48-sweeper-demonstrated-its-harvesting-robot-for-the-first-time you can also view a video demonstration via this webpage)

You may have recently heard or seen the new prototype capsicum robot picking machine. It is undeniably brilliant, but still far from the finished article. After I watched the video I read the comments posted in regards to the robot, to my bemusement over half of the comments were negative towards this machine. There is no doubt some people are worried about low income picking jobs that will be lost once inventions, like the capsicum picking robot, have been perfected but what are the drivers behind the need for such inventions.

It is all well and good to say inventions like this are going to be putting low income workers out of jobs, but innovation has been happening since the beginning of time. We could quite easily say that tractors put horses and labourers out of jobs when they started ploughing through the fields. This is just one of hundreds of examples that I could make but I think you understand my point. Innovation and new technology are everywhere. Emotion must be put to the side. Common sense and more discussion need to happen so we have an understanding as to why growers want and need this type of technology to maintain and possibly expand their businesses.

The fact is for greenhouse growers labour is a major expense, and if your business is cutting a fine line between making a profit or not, and you have exhausted all other avenues, then labour will constantly be analysed. Despite what many may think growers don’t make huge profits. Growers are generally not driving Jags and BMW’s. I have been a grower and most that will read this are growers, so you understand. For larger companies there is always pressure to increase profit levels year on year. The reason I single out larger companies and not smaller ones is that they will possibly be the only ones able to purchase such robots initially because of the capital investment needed (I make an assumption that the picking robots will be expensive).

Countries that have been investing into the picking robots are first world countries which have high labour cost compared to other countries where labour is relatively cheap, for example Mexico. To stay competitive with countries with no, or extremely low, minimum wage is a key driver. As we know here in New Zealand the minimum wage is going up, which is great for low income workers, but not so great for growers who can’t see a way in which they will recoup the increase they are going to have to pay. Potentially the invention of the capsicum picking robot will give some advantage back to the growers who can afford to purchase them. For the smaller grower whose payback might be slower, it will come down to numbers, the more robots that are purchased and manufactured, hopefully the more affordable they will become. I just hope smaller growing businesses are able to survive until they can afford such inventions.

There will be other huge advantages for growers, they won’t have to worry about having staff working on public holidays, paying extra holiday pay, ACC, PAYE, and the list goes on! For people who are not growers you can’t just stop the plant growing on a Friday and come back and turn the switch back on Monday. And if you have to pick every second or third day you are left with no options at certain times of the year to have staff work on public holidays.

Growers have no say in government policy, they are made by politicians believing they are doing the right thing, and I am for one not going to say they are wrong but their policies have forced the hands of growers which to be fair are creating jobs in other sectors in this case the design and manufacturing of robots. Picking robots will need maintenance and a different potentially higher skilled worker to oversee them, which will also create jobs in the greenhouse. My message is please do not blame growers or politicians, these are just the actions and reactions of policy. Look at the positives.

A famous quote from Albert Einstein

Stay away from negative people. They have a problem for every solution.

If you wish to read more on this subject, I was alerted to the following article:

The idea that manual work can be carried out by machines is already familiar; now ever-smarter machines can perform tasks done by information workers, too. What determines vulnerability to automation, experts say, is not so much whether the work concerned is manual or white-collar but whether or not it is routine.

Yet in the past technology has always ended up creating more jobs than it destroys. That is because of the way automation works in practice, explains David Autor, an economist at the Massachusetts Institute of Technology. Automating a particular task, so that it can be done more quickly or cheaply, increases the demand for human workers to do the other tasks around it that have not been automated.

(To read more click the link below)

https://www.economist.com/special-report/2016/06/25/automation-and-anxiety

Pictures of the Sweeper below:

I appreciate your comments. Please feel free to comment below or on the grower2grower Facebook page:

https://www.facebook.com/StefanGrower2grower/

Article Written by Stefan Vogrincic, Consultant, Grower2Grower

CLASSIFIED

Subscribe to our E-Zine

More

From This Category

John van Santen joins the management of Metazet

Metazet Completes Greenhouse Installation in 2 Days for New R&D Greenhouse

Bale Breaker, Just Press Play

Introducing Moleaer’s Trinity: Revolutionizing Agriculture with Advanced Nanobubble Technology

Punchbowl Packaging – Bagasse trays have replaced their conventional black PET counterparts.