Sign up here to subscribe to the Grower2grower Ezine. Every two weeks you will receive new articles, specific to the protected cropping industry, informing you of industry news and events straight to your inbox.

“Exciting results in our project that warrants optimism”

It has been three months since the first article was posted in regards to the work Jeremy Aditya Prananto has been researching on near-infrared technology for monitoring crop health conditions. I approached Jeremy for an update; below is some of the intriguing preliminary findings.

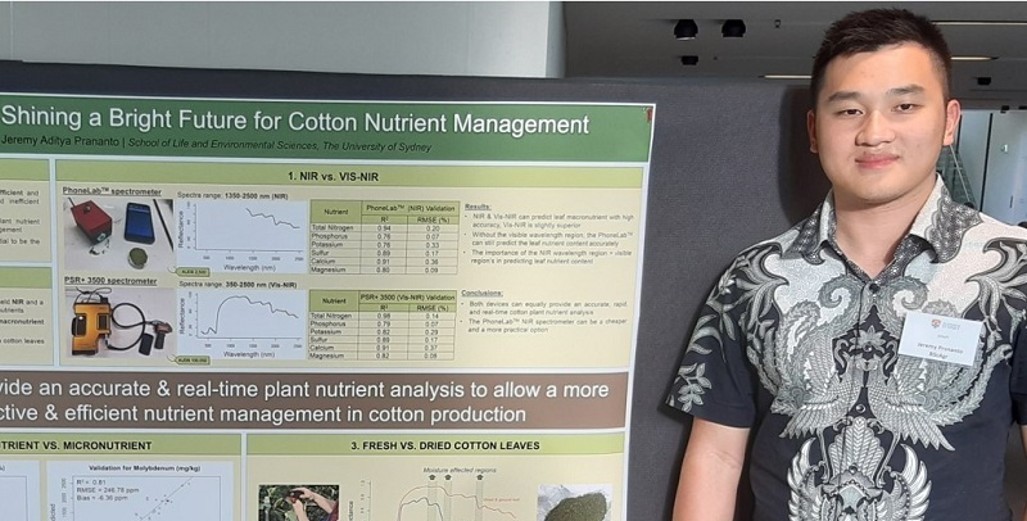

Three months have passed since I presented my preliminary findings, at the Protected Cropping Australia (PCA) conference in Gold Coast, I have finally finished my honours project. Following up on the article released (news/post/student-jeremy-aditya-prananto-presentation-captured-my-attention–pca-/ ) in the Grower2Grower edition 14, we have found some exciting results in our project that warrants optimism.

The projects aims to use a handheld near infrared (NIR) sensor as a rapid and real-time plant nutrient analysis for a more efficient crop nutrient management. We collected a large number of cotton leaf samples, from various regions around Narrabri, NSW. We took the leaf samples to the lab and then scanned them with the NIR sensor. We also sent the samples to the laboratory for conventional analysis to validate our results. We then built models to accurately estimate macro- and micronutrients in plant leaf tissues just from leaf NIR signature.

The NIR sensor can estimate plant macronutrients accurately: total Nitrogen (accuracy of 94%), Phosphorous (76%), Potassium (76%), Calcium (91%), Magnesium (80%), and Sulphur (89%). Additionally, our models are also able to estimate essential micronutrients successfully, which includes iron (accuracy of 70%), Manganese (75%), Copper (65%), Molybdenum (73%), Boron (64%), and Sodium (76%).

We are able to attribute the high prediction accuracy for macronutrients in particular N, P, and S as they mostly exist as organic compounds in leaf tissues. NIR sensor is particularly sensitive to the chemical bonds that make up organic compounds e.g., proteins.

The observed vs predicted plot of the models on the validation dataset which shows the prediction accuracy of the model. The R2 shows the accuracy, RMSE shows the error of the model, and the Bias shows if there is any over or under prediction in the model. All the parameters show a very accurate model despite being a validation.

Micronutrients and other macronutrients such as Ca, Mg, and K exist mostly as inorganic compounds that cannot be directly detected through NIR. However, these nutrients can still be well estimated as they are highly correlated to other organic compounds.

As macronutrients have higher concentration in the leaves, they can be estimated very accurately. Meanwhile, micronutrients that have lower concentrations would be more challenging to estimate. Nevertheless, overall we are still able to estimate most micronutrients for practical applications.

Our findings show that the handheld NIR sensor can be used to accurately predict the nutrient status of fresh leaves. This ability to rapidly acquire nutrient status information from the crops can potentially be used as a tool for a more efficient fertiliser application, where the application rate can be continuously adjusted based on the crop’s nutrient status which is a good indicator of the crops fertiliser requirement.

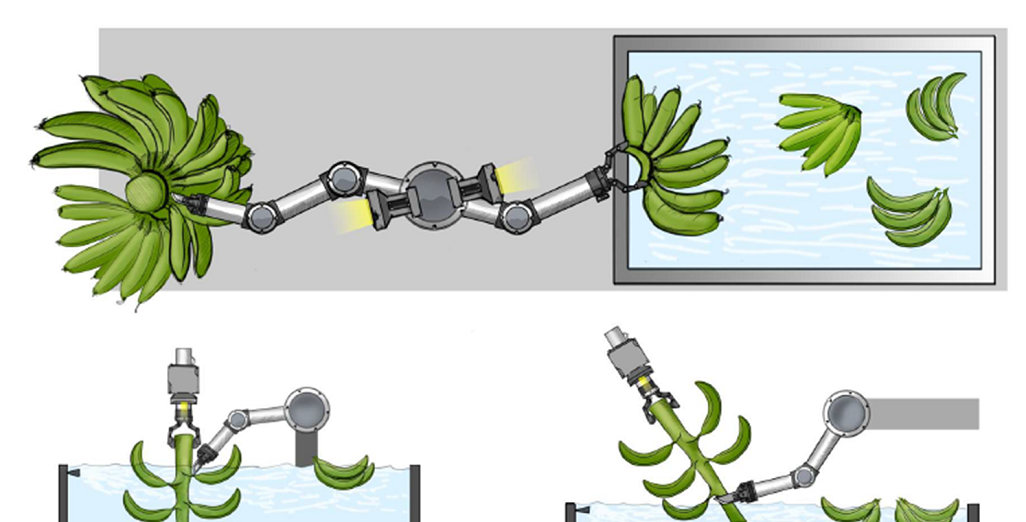

Future studies are required to establish a protocol that would take advantage the full potential of this technology. Automation of this technology in the glasshouse is the next step, where it will be linked to micro-decisions on fertiliser application rate.

The handheld NIR in action scanning fresh leaves in glasshouse.

Above Jeremy with his poster during the USYD undergraduate SOWwFI conference on the 13 Nov 2019.

Appreciate your comments. Please feel free to comment below or on the grower2grower Facebook page:

https://www.facebook.com/StefanGrower2grower/

Article content supplied by Jeremy Aditya Prananto

Article Edited by Marie Vogrincic, Editor, Grower2Grower

CLASSIFIED

Subscribe to our E-Zine

More

From This Category

John van Santen joins the management of Metazet

Metazet Completes Greenhouse Installation in 2 Days for New R&D Greenhouse

Bale Breaker, Just Press Play

Introducing Moleaer’s Trinity: Revolutionizing Agriculture with Advanced Nanobubble Technology

Punchbowl Packaging – Bagasse trays have replaced their conventional black PET counterparts.